Basic Info.

Model NO.

MMR

Condition

New

Customized

Customized

Warranty

1 Year

After-Sales Service

Online Support

Applicable Industry

Farms, Energy & Mining, Chemical Fertilizer

Load Capacity

8t/H- 220t/H

Color

Based on Your Demands

Speed

1.25-1.6m/S

Transport Package

Wooden Box

Specification

based on model

Trademark

AGS

Origin

Zhenjiang

HS Code

84742090

Production Capacity

10000sets/Year

Product Description

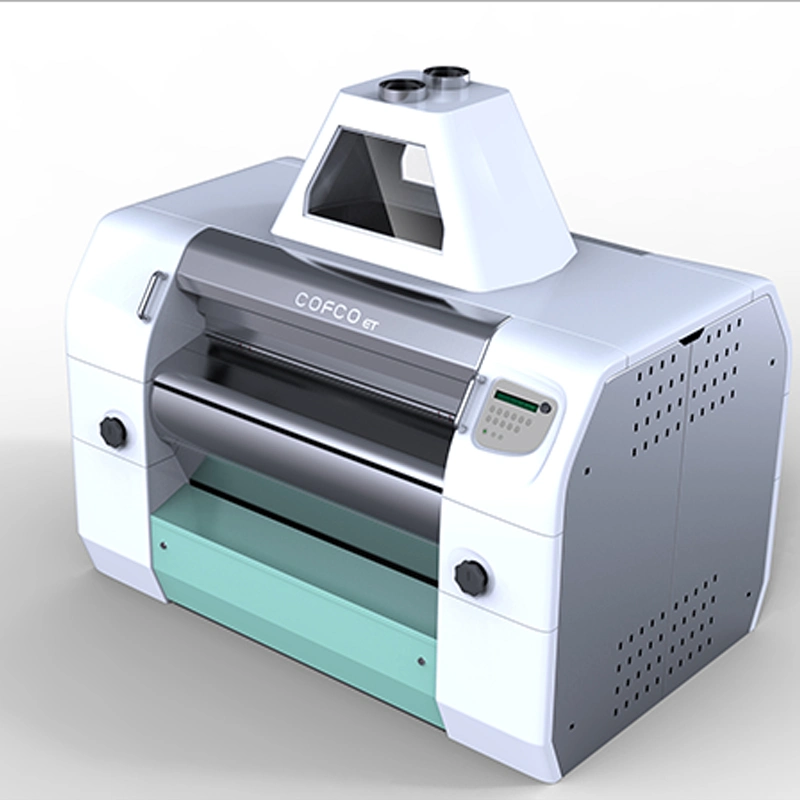

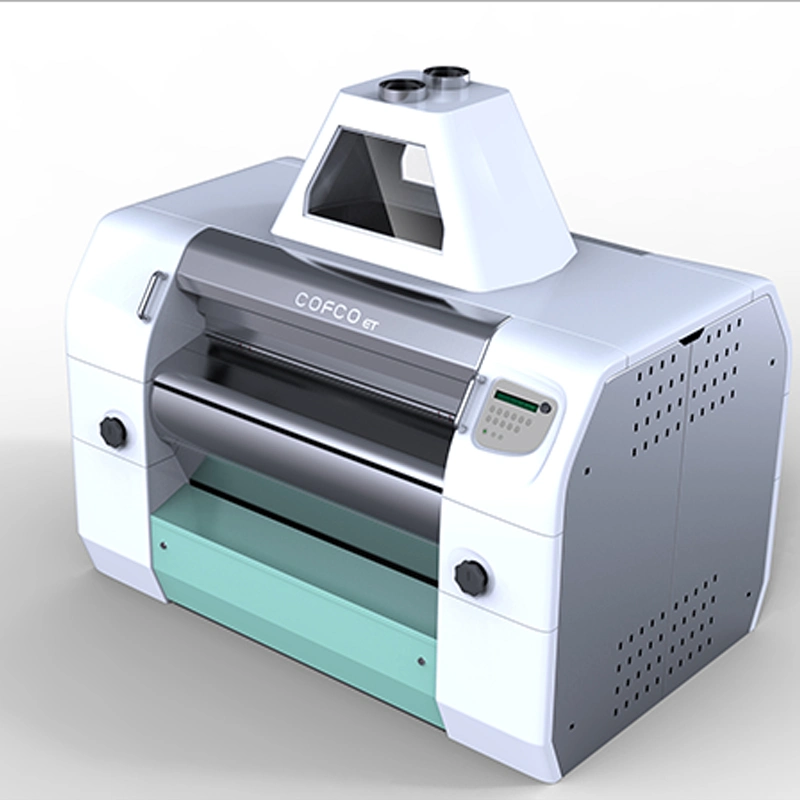

MMR Roller Mill

Roller mill is the main equipment for milling section in flour mills. The wheat is stripped mainly by a pair of grinding rollers with speed difference and relative rotation and ground into flour when endosperm is peeled off from wheat bran.

MMR mill is high-end products, leading the future market. The contact part of material is made of food-grade 304 stainless steel, no dead angle, no residue;

1- Easy to flip the feeding unit, easy to clean the feeding area;

2- The grinding roller unit, a spin off from the grinding body assembly, convenient operation reducing paring time;

3- Variable speed feeding, the feed will increase to the limitation, change the feeding environment, improving the grinding quality and saving energy;

4- Permanent magnet synchronous motor speed control, and more efficiency than ordinary motor, cleaner;

5- Tooth elastic wedge band tensioning device can self-compensate the micro-change and improve the service life of the band;

6- The whole case iron base, higher stability of equipment.

Core technologies & Achievements

• Engineering Procurement Construction

• Engineering Design

• Consultation

• Research And Development

Core Technology

ABOUT AGS

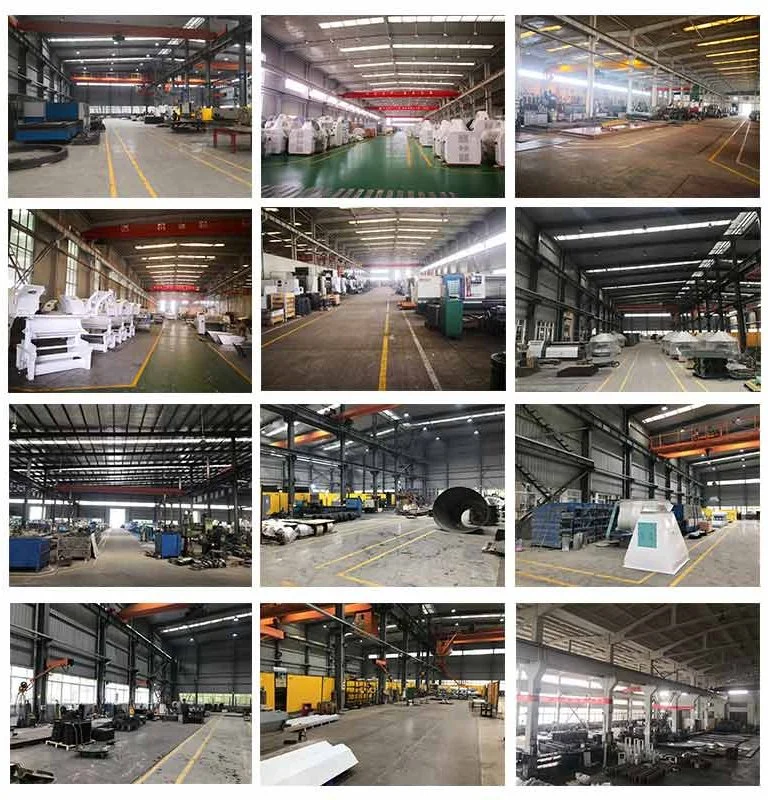

Zhenjiang AGS Machinery Co., Ltd manufacture and export conveyor parts in China, Our business area are screw conveyor, chain conveyor, belt conveyor, bucket elevator, Roller mill, Purifier Bin Filter, spout pipe, sieve cleaner, chain ,all kind of machines and components for flour mill ,feed mill, rice mill , and other bulk material handling industry.Our products have exported to South Asia, South Africa, West Africa, South American and Russia and the Philippines.All the products are tested before delivery according to relevant International Standard or customers' requirements.Besides the international standard products, we can also design and manufacture new products according to drawings or requirements.With more than 20 years experience in the bulk material handling industry, we hope to become one-stop suppliers for all the different machines and components.

Roller mill is the main equipment for milling section in flour mills. The wheat is stripped mainly by a pair of grinding rollers with speed difference and relative rotation and ground into flour when endosperm is peeled off from wheat bran.

MMR mill is high-end products, leading the future market. The contact part of material is made of food-grade 304 stainless steel, no dead angle, no residue;

1- Easy to flip the feeding unit, easy to clean the feeding area;

2- The grinding roller unit, a spin off from the grinding body assembly, convenient operation reducing paring time;

3- Variable speed feeding, the feed will increase to the limitation, change the feeding environment, improving the grinding quality and saving energy;

4- Permanent magnet synchronous motor speed control, and more efficiency than ordinary motor, cleaner;

5- Tooth elastic wedge band tensioning device can self-compensate the micro-change and improve the service life of the band;

6- The whole case iron base, higher stability of equipment.

| Items | Unit | Specification | |||

| Model | MMR25/1250 | MMR25/1000 | MMR25/800 | ||

| Roll Diameter x Length | mm | ∮250 x1250 | ∮250 x1000 | ∮250 x800 | |

| Diameter Range of Roll | mm | ∮250--∮230 | |||

| Fast Roll Speed | r/min | 450-650 | |||

| Gear Ratio | 1.25:1 1.5:1 2:1 2.5:1 | ||||

| Feed Ratio | 1:1 1.4:1 2:1 | ||||

| Half Equipped with Power | Motor | 6 Grade | |||

| Power | KW | 37,30,22,18.5,15,11,7.5,5.5 | |||

| Main Driving Wheel | Diameter | Mm | ∮360 | ||

| Groove | 15N(5V)Type 6Grooves 4Grooves | ||||

| Working Pressure | Mpa | 0.6 | |||

| Dimension(L x W x H) | mm | 2060x1422x1997 | 1810x1422x1997 | 16110x1422x1997 | |

| Gross Weight | kg | 3800 | 3200 | 2700 | |

Core technologies & Achievements

• Engineering Procurement Construction

• Engineering Design

• Consultation

• Research And Development

Core Technology

ABOUT AGS

Zhenjiang AGS Machinery Co., Ltd manufacture and export conveyor parts in China, Our business area are screw conveyor, chain conveyor, belt conveyor, bucket elevator, Roller mill, Purifier Bin Filter, spout pipe, sieve cleaner, chain ,all kind of machines and components for flour mill ,feed mill, rice mill , and other bulk material handling industry.Our products have exported to South Asia, South Africa, West Africa, South American and Russia and the Philippines.All the products are tested before delivery according to relevant International Standard or customers' requirements.Besides the international standard products, we can also design and manufacture new products according to drawings or requirements.With more than 20 years experience in the bulk material handling industry, we hope to become one-stop suppliers for all the different machines and components.