Basic Info.

Model NO.

GMJY-500

Bulking Machine Type

Twin Screw Bulking Machine

Expanding Method

Dry Expansion

Condition

New

Applicable Materials Shape

Powder

Capacity(Kg/H)

500

Key Word 1

Pellet Machine

Key Word 2

Mixer Machine

Crusher Motor(Kw)

5.5

Transport Package

Wooden Cases

Specification

2000*1050*2500

Trademark

RX

Origin

Henan

Production Capacity

500000

Product Description

1t/h feed machinery cattle animal feed crusher and mixer hammer mill

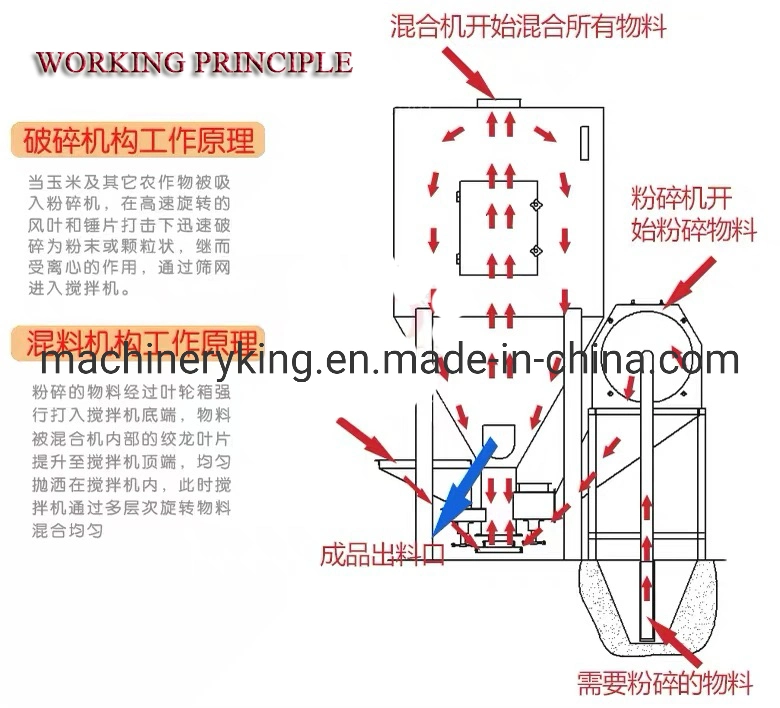

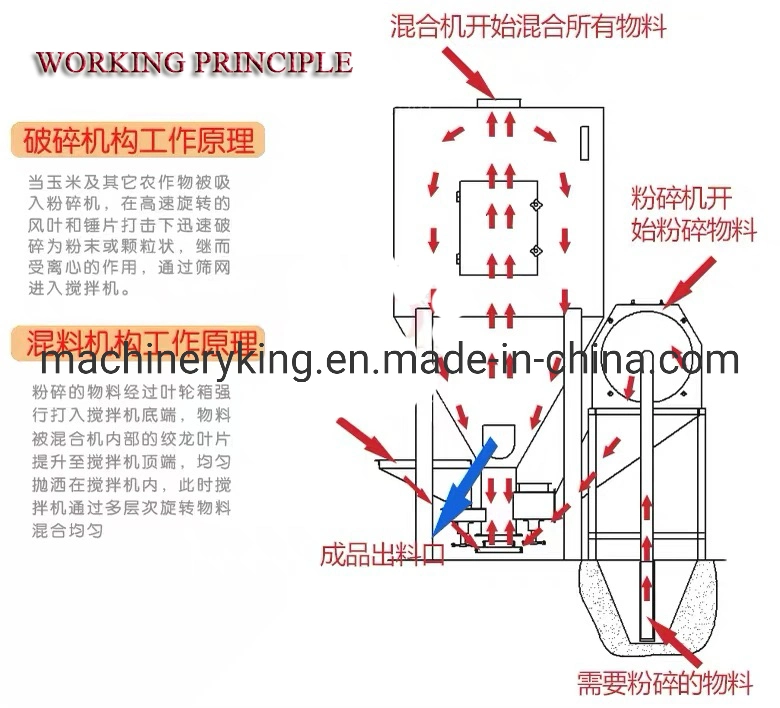

Working principle:

With simple and compact structure, small one-time investment, economical and practical, convenient maintenance, without special manufacturing site.

Feed Processing Machines small farm Wheat Corn Feed Mill Crusher mixer can be divided into two parts, including crushing structure and mixing structure.

The mixing structure: The mixer impeller transport the mash feed to the main shaft of mixer while mash feed are sent to the mixer top by screw, then powder feeds are poured down along the wall of mixer. Repeat this process until the feed is blend.

The grinder structure :is made of high quality material welded together,the inlet at the top of the grinder can be matched with various forms offeeding structure, the hammer is arrangedsymmetrically.Mill work, the materials enter the crushing chamber, in the high-speed rotary hammer blow and sieve-plate under the action of friction, material being crushed ,and under the action of centrifugal force and air flow. Discharged through the bottom outlet.

Description:

Animal feed mixer machine barley crusher malt grain mill has been widely used in the raw material grinding of the large and medium scale feed factory, alcohol plant, food products factory and so on. Animal feed crusher and mixer hammer mill Raw materials can crush corn, wheat, soybean and any kinds of grains to powder,also can mixer together .using for chicken farms, pig feed mills and other feed farmers.

1. Introduction of animal feed crusher and mixer machine:

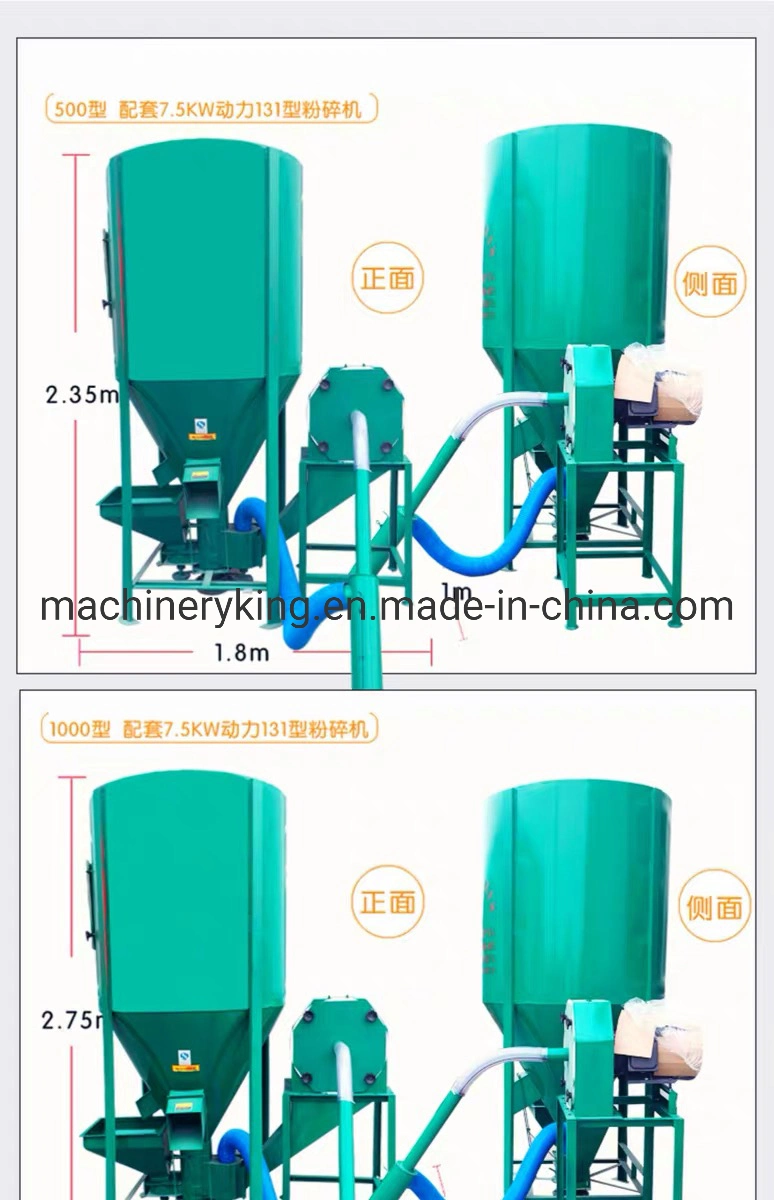

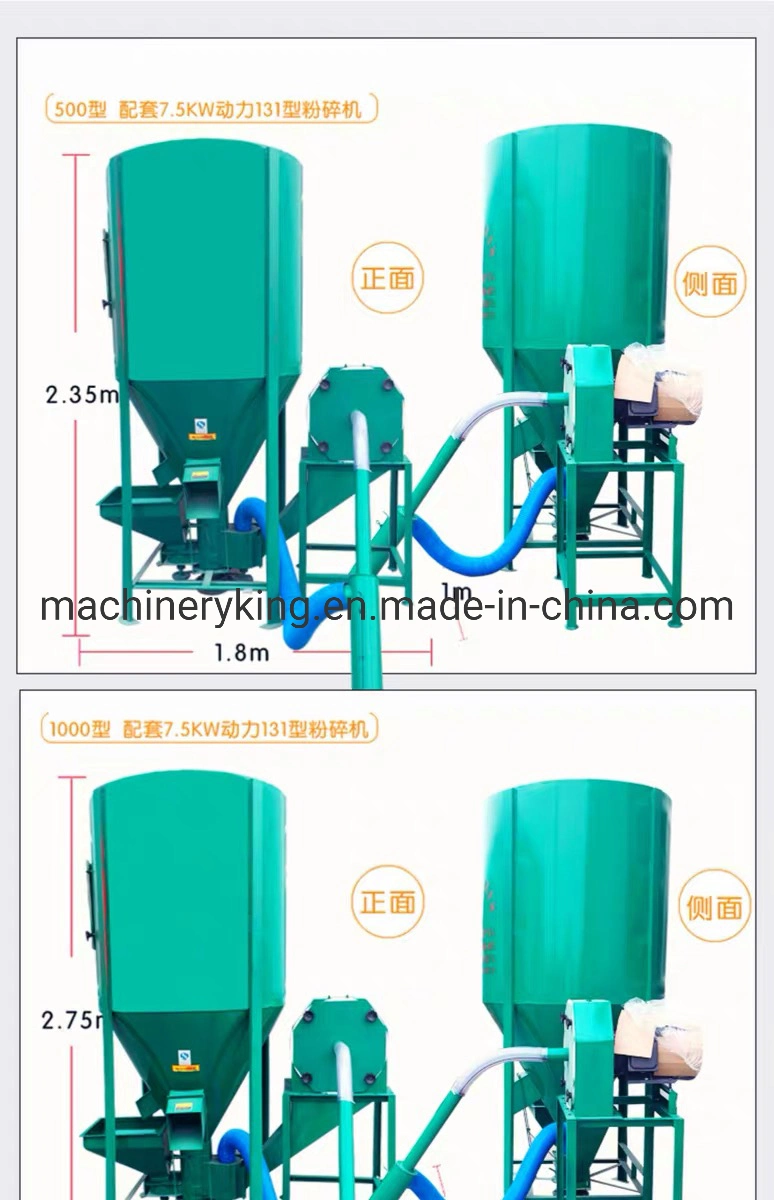

This 2 in 1 animal feed crusher and mixer is vertical type which saves your room and saves your price cost and absorb the raw materials by itself,completely automatically feeding.

This animal feed crusher and mixer is mainly used to crushing and mixing kinds of raw materials to produce poultry feed.

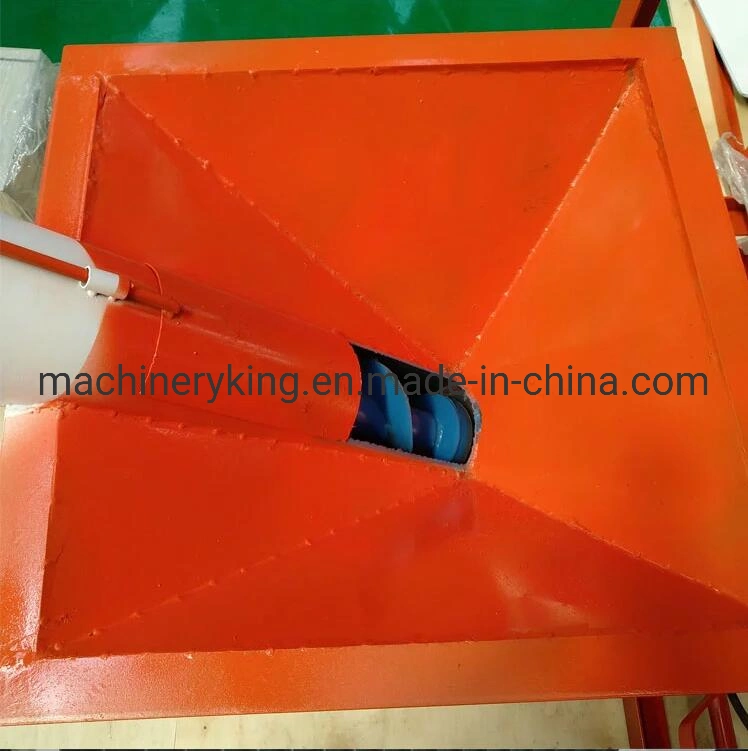

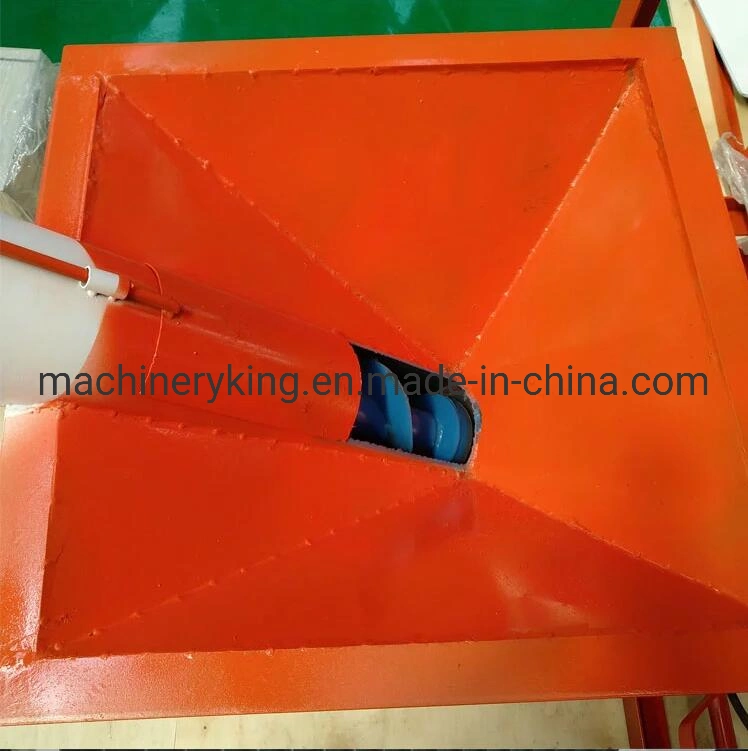

The crushing part is hammer mill grinder with feature of absorbing the raw materials automatically,the mixing part is vertical screw type,feeding raw materials through a screw conveyor.

This type vertical feed grinder and mixer is concentrated with conveyor, feed crushing machine, feed mixing machine into one equipment which makes it occupy a small room and high cost performance.

The production scale is from 500 kilograms per hour to 2000 kilograms per hour which is suitable for small poultry farm or home use to make powder animal feed.it is usually used with feed pellet machine to set up a small feed pellet production plant. because of the impressed feature of 2 in 1, you save using separated feed crusher machine and feed mixer machine

2. Features of animal feed crusher and mixer machine

1. It absorbs the raw materials automatically by itself

2. Vertical 2 in 1 type makes it occupy small room

3. It can be used for kinds of raw materials like grains,grass,straw

4. It can be driven by diesel engine or electricity motor.

Technical information:

Packing:

♥Wooden or metal case according to specific size of each equipment, we twine thick plastic coating for each machine.

♥Tight the equipment in the truck without space to ensure no rubbing during the transportation.

Working principle:

With simple and compact structure, small one-time investment, economical and practical, convenient maintenance, without special manufacturing site.

Feed Processing Machines small farm Wheat Corn Feed Mill Crusher mixer can be divided into two parts, including crushing structure and mixing structure.

The mixing structure: The mixer impeller transport the mash feed to the main shaft of mixer while mash feed are sent to the mixer top by screw, then powder feeds are poured down along the wall of mixer. Repeat this process until the feed is blend.

The grinder structure :is made of high quality material welded together,the inlet at the top of the grinder can be matched with various forms offeeding structure, the hammer is arrangedsymmetrically.Mill work, the materials enter the crushing chamber, in the high-speed rotary hammer blow and sieve-plate under the action of friction, material being crushed ,and under the action of centrifugal force and air flow. Discharged through the bottom outlet.

Description:

Animal feed mixer machine barley crusher malt grain mill has been widely used in the raw material grinding of the large and medium scale feed factory, alcohol plant, food products factory and so on. Animal feed crusher and mixer hammer mill Raw materials can crush corn, wheat, soybean and any kinds of grains to powder,also can mixer together .using for chicken farms, pig feed mills and other feed farmers.

1. Introduction of animal feed crusher and mixer machine:

This 2 in 1 animal feed crusher and mixer is vertical type which saves your room and saves your price cost and absorb the raw materials by itself,completely automatically feeding.

This animal feed crusher and mixer is mainly used to crushing and mixing kinds of raw materials to produce poultry feed.

The crushing part is hammer mill grinder with feature of absorbing the raw materials automatically,the mixing part is vertical screw type,feeding raw materials through a screw conveyor.

This type vertical feed grinder and mixer is concentrated with conveyor, feed crushing machine, feed mixing machine into one equipment which makes it occupy a small room and high cost performance.

The production scale is from 500 kilograms per hour to 2000 kilograms per hour which is suitable for small poultry farm or home use to make powder animal feed.it is usually used with feed pellet machine to set up a small feed pellet production plant. because of the impressed feature of 2 in 1, you save using separated feed crusher machine and feed mixer machine

2. Features of animal feed crusher and mixer machine

1. It absorbs the raw materials automatically by itself

2. Vertical 2 in 1 type makes it occupy small room

3. It can be used for kinds of raw materials like grains,grass,straw

4. It can be driven by diesel engine or electricity motor.

Technical information:

| Model | Crusher motor(kw) | Mixer motor(kw) | Capacity(kg/h) | Volumem(cubic) | Dimension(mm) |

| GMJY-500 | 5.5 | 3 | 500 | 1 | 2000*1050*2500 |

| GMJY-750 | 7.5 | 3 | 750 | 1 | 2150*1160*2600 |

| GMJY-1000 | 11 | 3 | 1000 | 1.5 | 2400*1300*2900 |

| GMJY-1500 | 15 | 4 | 1500 | 2 | 2500*1400*3000 |

| GMJY-2000 | 18 | 4 | 2000 | 2 | 2700*1700*3060 |

Packing:

♥Wooden or metal case according to specific size of each equipment, we twine thick plastic coating for each machine.

♥Tight the equipment in the truck without space to ensure no rubbing during the transportation.