- Overview

- Product Description

- Product Details

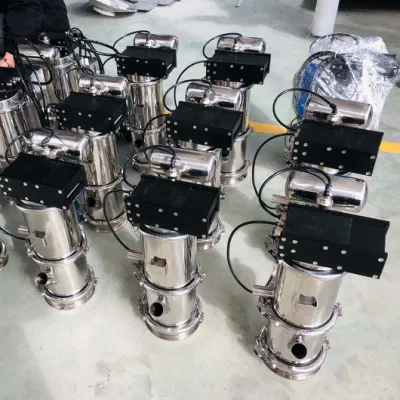

- Product Show

- Product Parameters

- Application Fields

- Packaging & Delivery

- Company Profile

- FAQ

Basic Info.

Packaging & Delivery

Product Description

Pneumatic vacuum conveyor is a versatile equipment used for efficient material transfer. It consists of a conveying pipe, vacuum pump, and control system. Using negative pressure, it transports powders and granules from one location to another.

The system ensures clean and contamination-free transfer, making it suitable for industries like chemical and food processing.

Its advantages include precise and continuous conveying, reduced manual handling, and improved productivity. The vacuum conveyor system is an ideal choice for automating material feeding and conveying processes, enhancing efficiency in various industries.

Structure

Main Features

Main Features

2. Automation and labor reduction: Automates material transfer, improving productivity and reducing labor costs.

3. Precise control: Easily adjusts conveying speed and capacity for precise material flow control, reducing spillage risk.

4. Versatility and material compatibility: Handles various materials, adapting to diverse production needs.

5. Dust-free operation: Minimizes dust emissions, creating a safer, cleaner work environment.

Pneumatic vacuum conveyor is used for material transfer, automated feeding, cross-contamination prevention, dust control, and process optimization, offering an efficient, clean, and automated solution for material handling in industrial production.

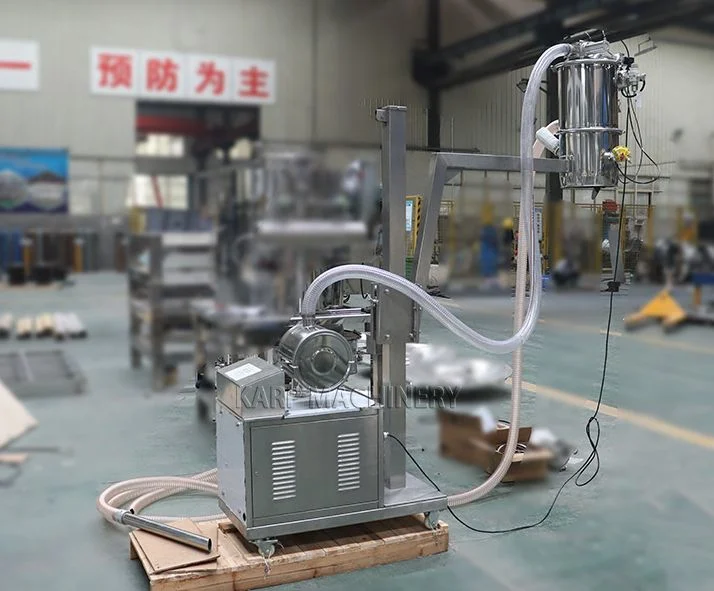

Lifting rods and mobile trolleys can be added for flexible transportation

Type 1: ZKJ Vacuum conveyor with pump is equipped with manual lifting device & movable trolley, discharge height can be adjustable manually, up to 2 m. | Type 2: ZKJ Vacuum feeder with pump without lifting device, suitable discharge height above 2 m, the hopper can be placed directly above the inlet of the downstream machine. |

Type 3: QVC Pneumatic vacuum conveyor without vacuum pump model, small space, but large air consumption. | Type 4: ZKJ Hybrid vacuum feeder can work with full enclosed mixer, such as V-type mixer, 2D/3D mixer, double-cone mixer, etc. |

We will select different filter components for you according to different raw materials

| Model | Air consumption (L/min) | Hopper volume (L) | Air pressure (Mpa) | Capacity (kg/h) |

| QVC-1 | 180 | 1.1 | 0.4-0.6 | 400 |

| QVC-2 | 360 | 6 | 600 | |

| QVC-3 | 720 | 12 | 1200 | |

| QVC-4 | 1440 | 42 | 2500 |

Note: The conveying capacity is measured when the conveying tube is 4 meters long and the conveying material is flour. The longer the conveying tube is, the lower the conveying capacity is, and the conveying capacity is also greatly related to the characteristics of the material.

If you would like know more details, please contact us by clicking on the image below!

Aplication details:

1.Food and Beverage Industry: Conveying food additives, powdered ingredients, and granular materials in food production and processing.

2.Chemical Industry: Handling and conveying chemical powders, additives, and raw materials for various chemical processes.

3.Plastic Industry: Transporting plastic pellets, powders, and additives for plastic production and molding.

4.Grain processing industry: Transferring grains, flour, and feed ingredients.

Aplication site:

We warmly welcome friends from all over the world to our company, we are looking forward to sincere cooperation and mutually beneficial development with you.

CE Certificates

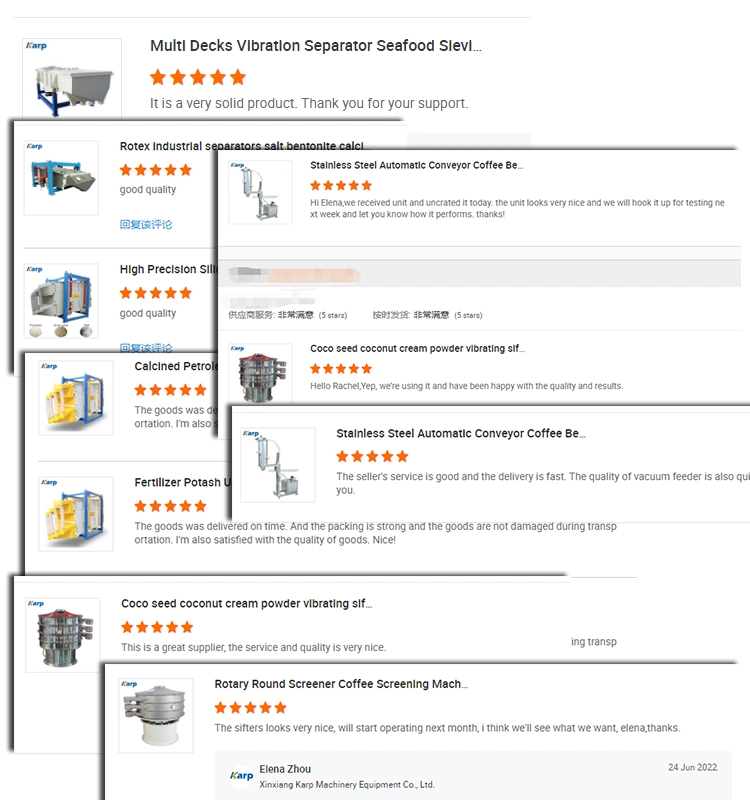

Our equipment has been widely praised:

1. Can I customize my product?

2. How long is your production time?

A set of equipment takes 15-20 working days, and more than 1 set takes about 20-25 working days.

3. How long is your warranty?

A 13-month warranty ensures you have no worries.

4. What services can we provide?

Accepted Delivery Terms: FOB, CFR, EXW;

Accepted Payment Currency: USD, EUR, HKD, CNY;

Accepted Payment Type: T/T, L/C, PayPal, Western Union;

Each product undergoes strict quality control before shipping, so please rest assured.

If you are interested, please let us know the following information:

1. What's the raw material information? And its specific gravity? Is it easy to flow?

2. What's the feeding distance? (Height of discharge __ meters? And the horizontal conveying length ___ meters?)

3. Conveying capacity __ kgs/h?

4. Which equipment does the vacuum feeder suck materials from and feed to?