Basic Info.

Model NO.

SFSP series or custom-made

Pellet Mill Type

Ring Die Pelleter

Bulking Machine Type

Twin Screw Bulking Machine

Expanding Method

Wet Expansion

Condition

New

Applicable Materials Shape

Granular

Warranty

5-6months(Spare Parts)

Material

Low/Medium Carbon Steel, Stainless Steel...

Usage

Spare Parts for Hammer Mill

Transport Package

Wooden Box

Specification

0.3-30mm hole diameter

Trademark

IKLAY

Origin

China

HS Code

846692

Production Capacity

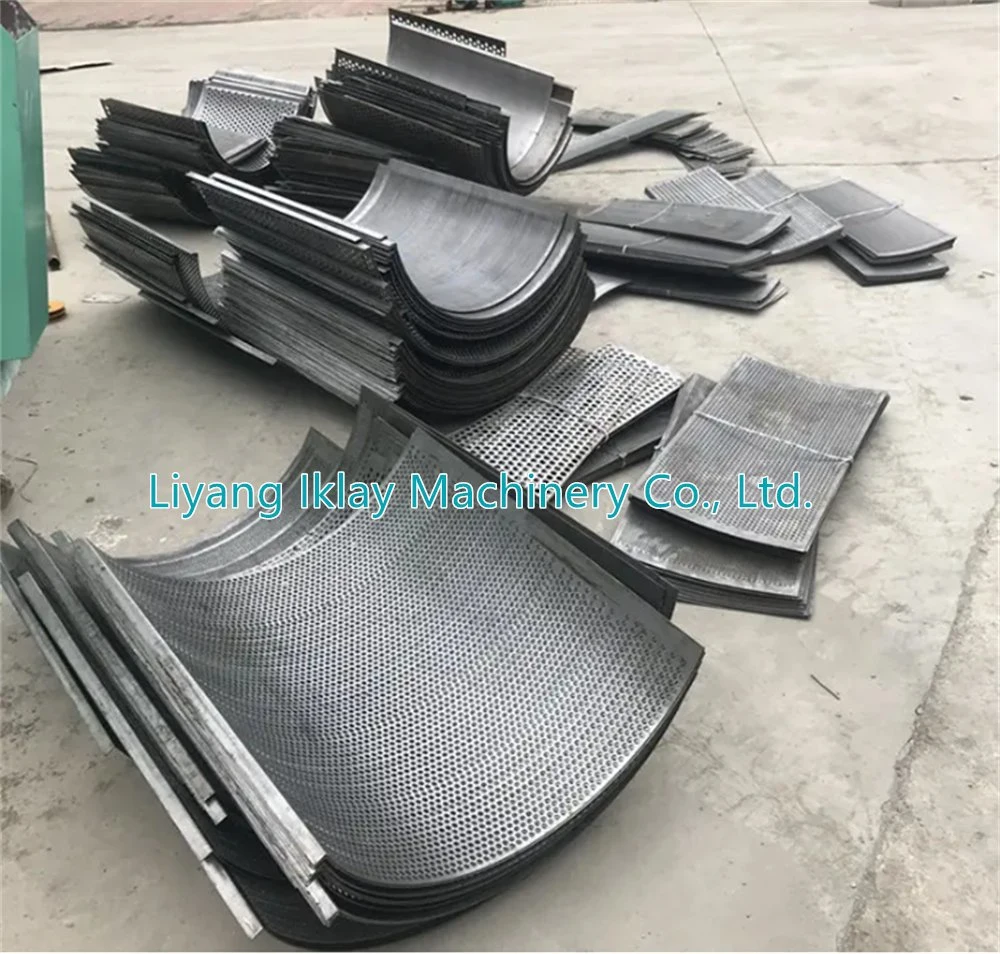

100000PCS/Month

Product Description

Introduction

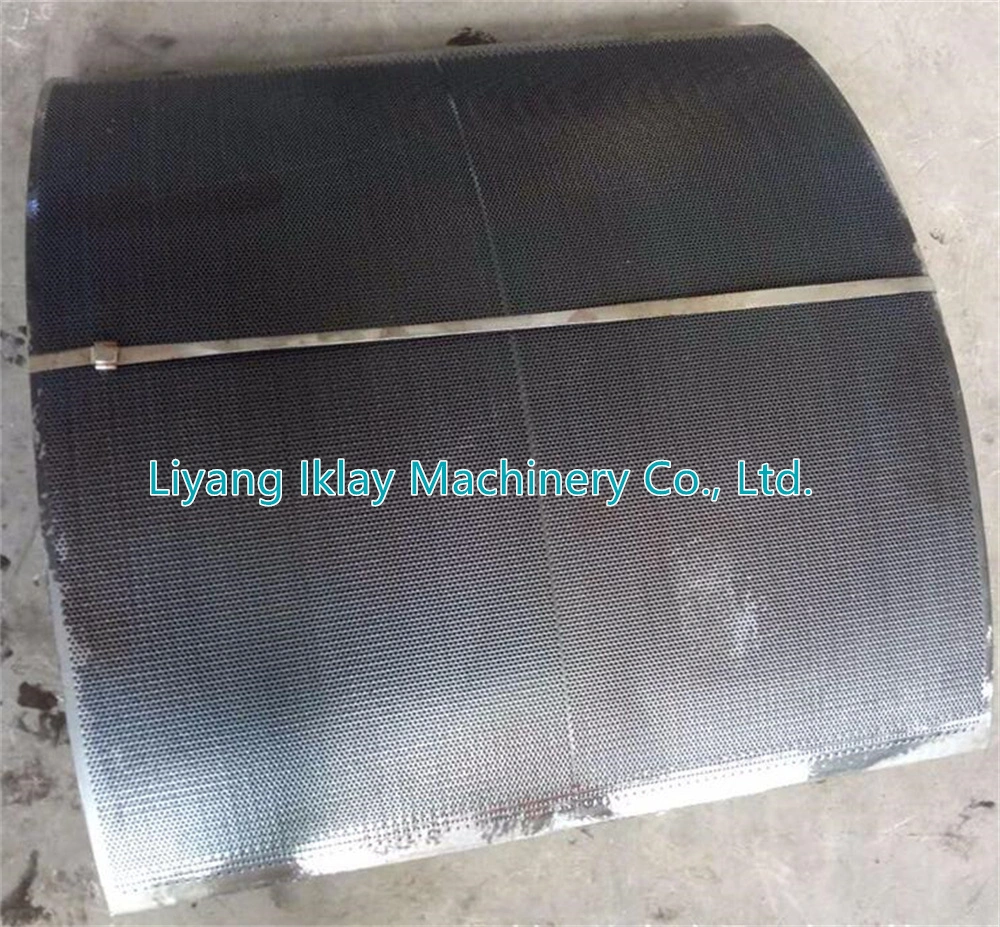

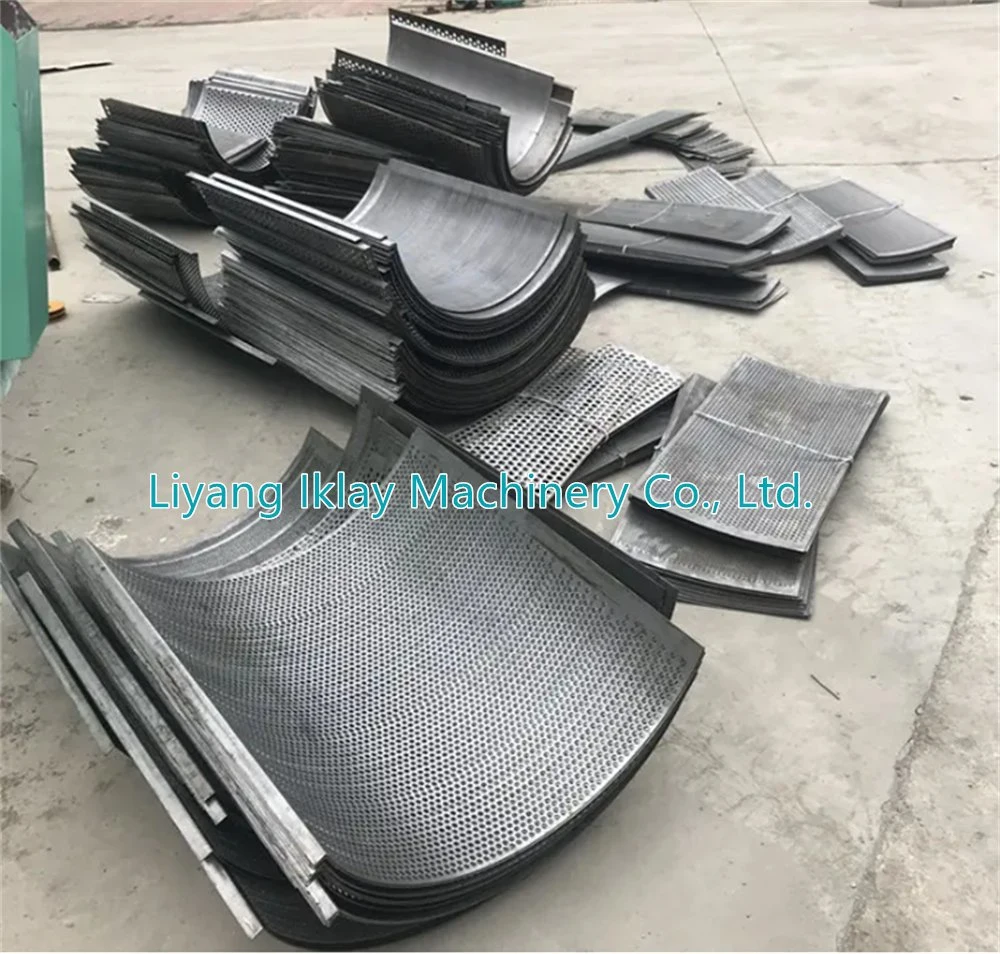

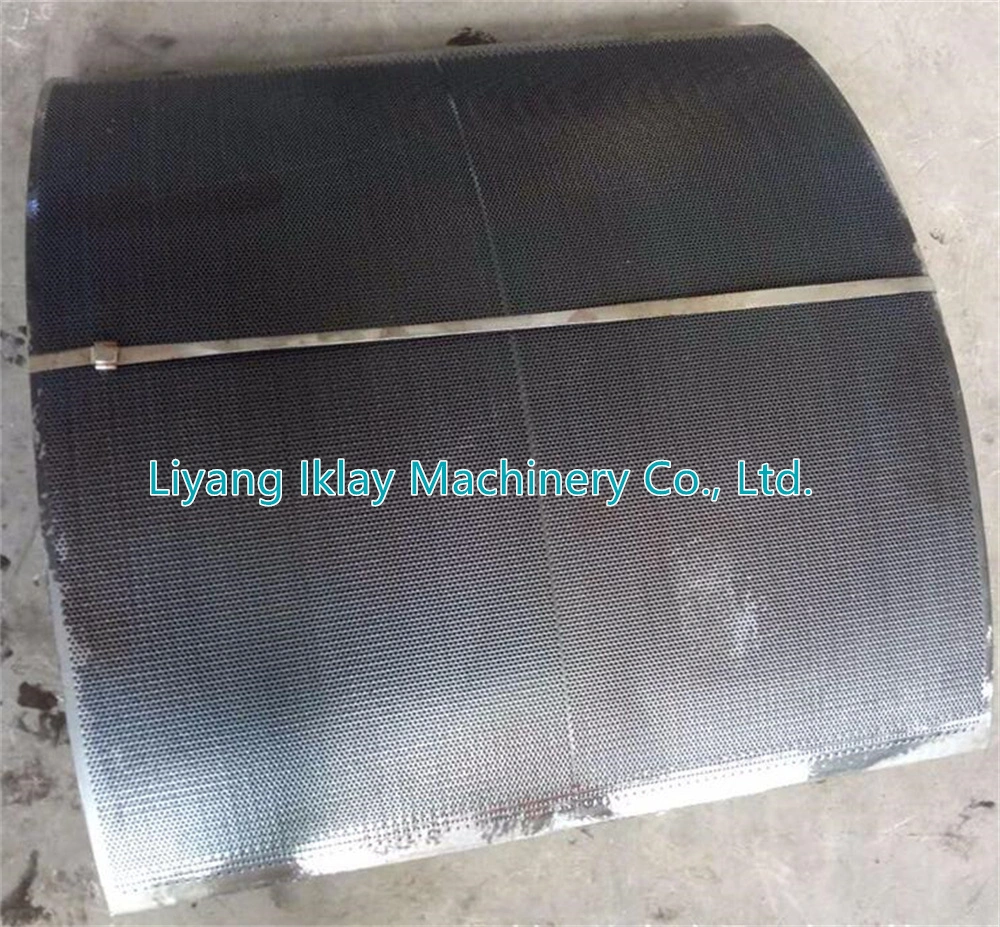

The screen sieves for hammer mill is the main accessory to control the fineness of the crushed product, and it is also one of the main wearing parts of hammer mill. Its type, shape, hole density, wrap angle and opening ratio all have an important influence on the crushing and screening effect. Generally, it is widely used in the fields of feeds, biomass pellets, medicine, food, chemical industry and so on.

Features

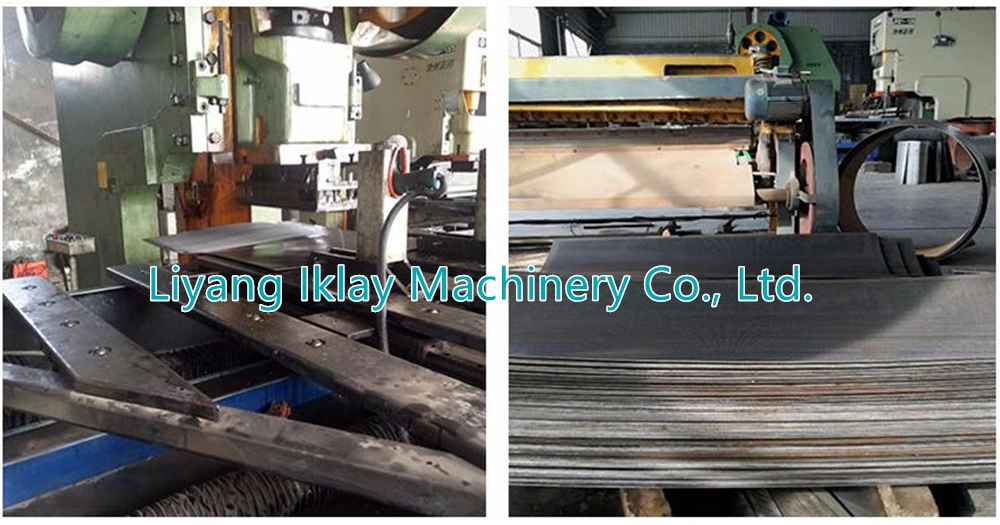

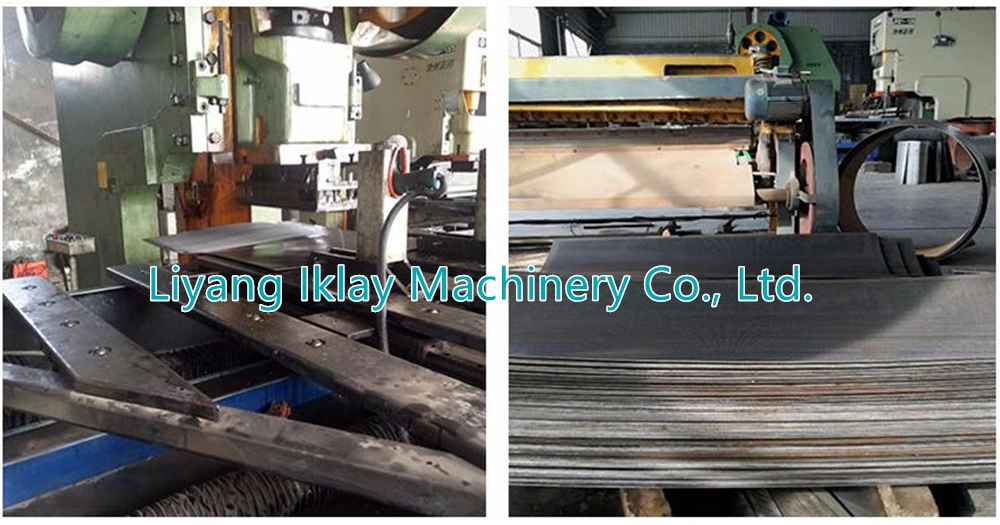

1. Mechanical stamping, the screen mesh is even and smooth

2. Selected thick and wear-resistant materials, stable structure and strong impact resistance

3. A variety of specifications and different apertures are available, support for customization

4. High temperature quenching, durable and wear-resistant, longer service life

5. No leakage of materials and labor&time saved. High porosity, high output and high benefits.

Photos

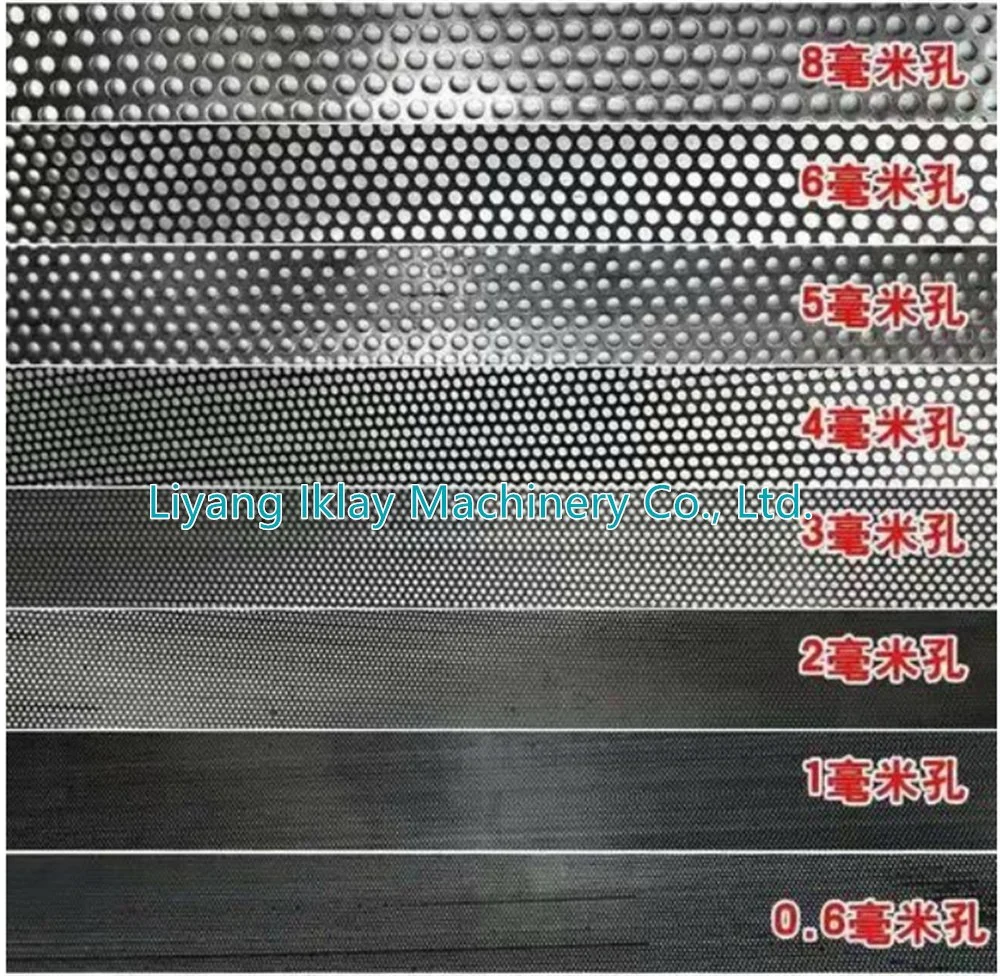

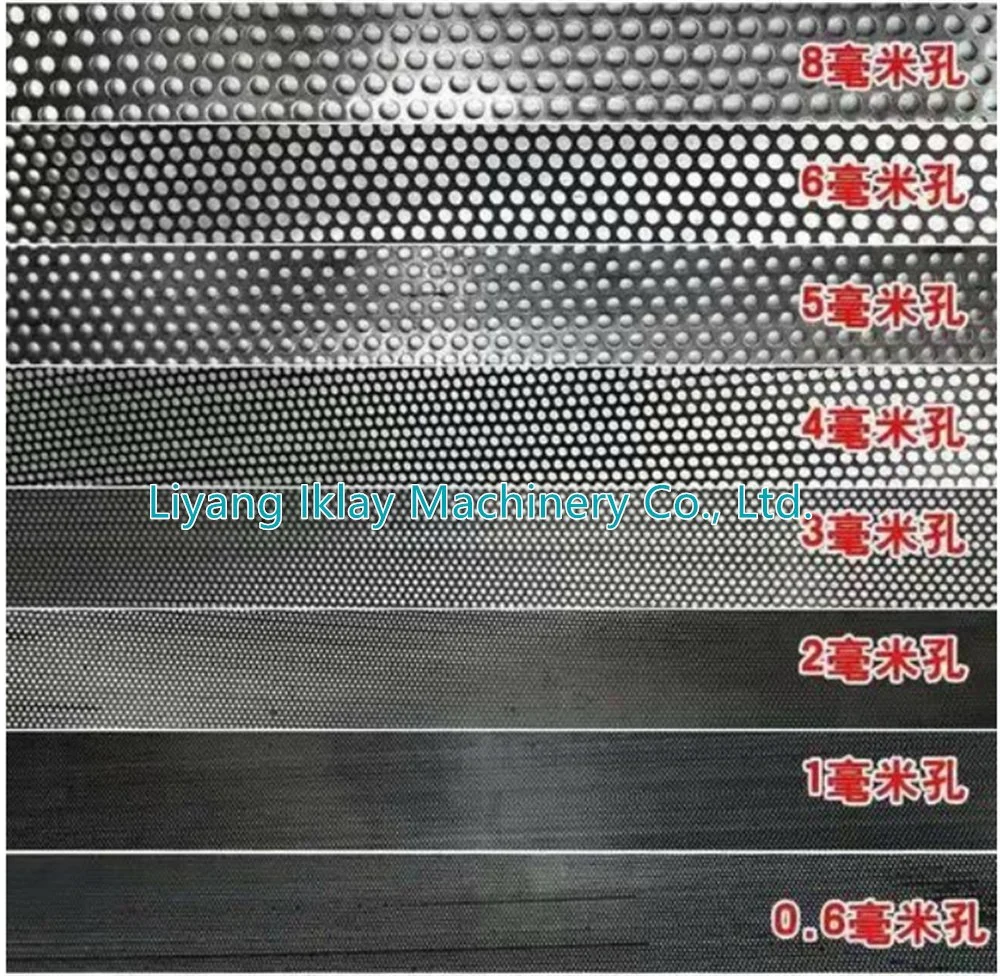

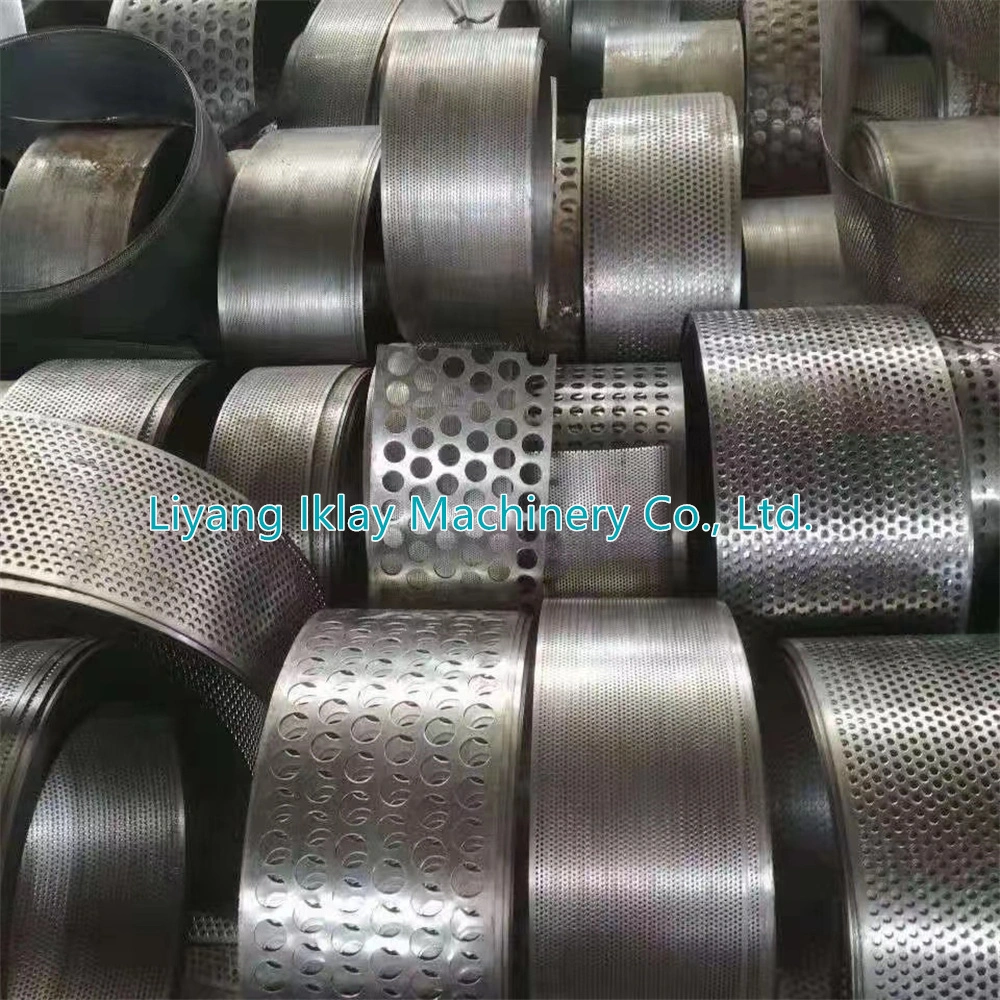

(Different hole diameters for hammer mill screen meshes)

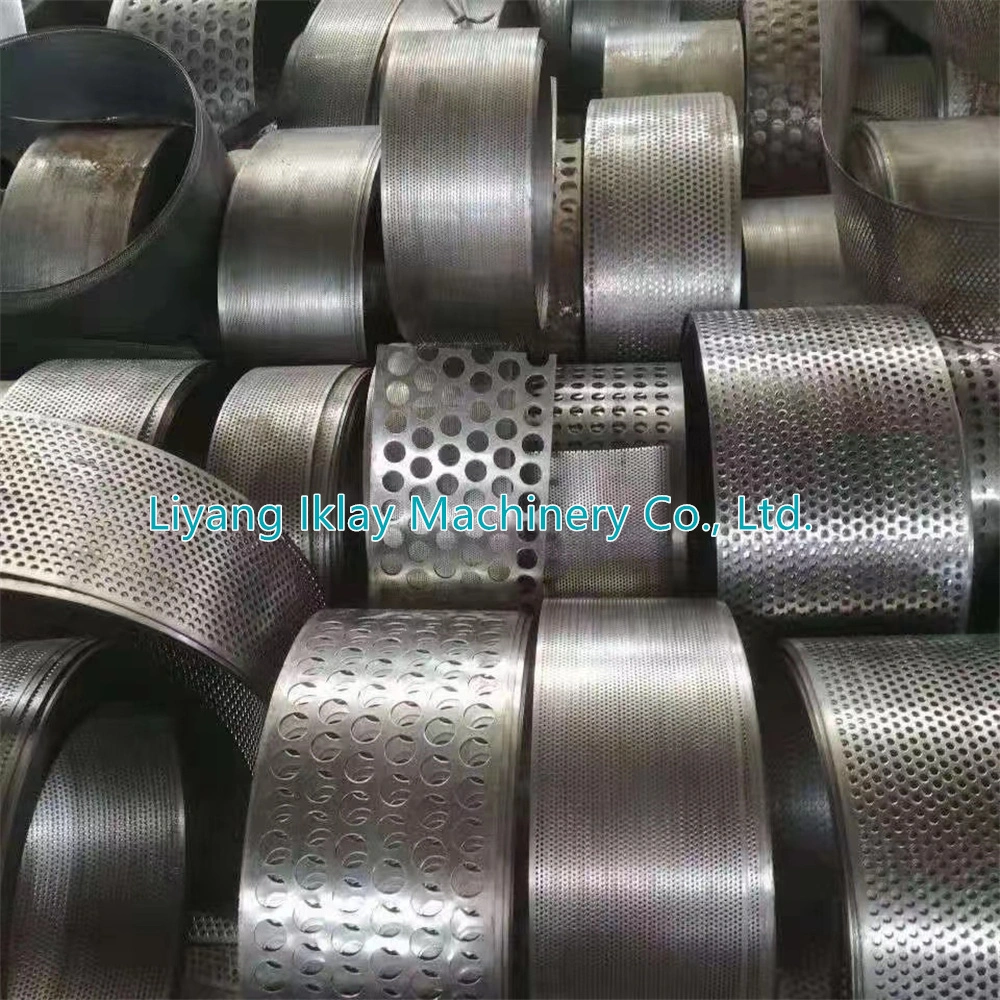

Liyang Iklay Machinery Co., Ltd. is a professional manufacturer and supplier specialized in designing, manufacturing, installing and commissioning: Poultry&livestock&aqua feed production line, Biomass pellet production line, Cat litter production line; Spare parts for hammer mill& pellet mill, such as ring dies, rollers, hammer blades and screens.

Liyang Iklay Machinery Co., Ltd. is a professional manufacturer and supplier specialized in designing, manufacturing, installing and commissioning: Poultry&livestock&aqua feed production line, Biomass pellet production line, Cat litter production line; Spare parts for hammer mill& pellet mill, such as ring dies, rollers, hammer blades and screens.

The screen sieves for hammer mill is the main accessory to control the fineness of the crushed product, and it is also one of the main wearing parts of hammer mill. Its type, shape, hole density, wrap angle and opening ratio all have an important influence on the crushing and screening effect. Generally, it is widely used in the fields of feeds, biomass pellets, medicine, food, chemical industry and so on.

Features

1. Mechanical stamping, the screen mesh is even and smooth

2. Selected thick and wear-resistant materials, stable structure and strong impact resistance

3. A variety of specifications and different apertures are available, support for customization

4. High temperature quenching, durable and wear-resistant, longer service life

5. No leakage of materials and labor&time saved. High porosity, high output and high benefits.

| Materials for hammer mill screens | Low carbon steel/ Medium carbon steel/ Stainless steel..... (Different materials for your choice) |

| Nitriding depth | >0.12mm |

| Surface hardness | >= HV450 |

| Hole type | Circular hole, Square hole, Shaped hole and etc. |

| Normal Hole diameter for screens | 0.3mm/ 0.4mm/ 0.5mm/ 0.6mm/ 0.8mm/1.0mm/ 1.2mm/ 1.5mm/ 2.0mm/ 2.5mm/ 3mm/ 4mm/ 6mm/ 8mm/ 10mm/ 12mm/ 20mm/ 30mm |

| Model of hammer mill | SFSP series or others |

| Special custom-made | Support |

Photos

(Different hole diameters for hammer mill screen meshes)

Liyang Iklay Machinery Co., Ltd. is a professional manufacturer and supplier specialized in designing, manufacturing, installing and commissioning: Poultry&livestock&aqua feed production line, Biomass pellet production line, Cat litter production line; Spare parts for hammer mill& pellet mill, such as ring dies, rollers, hammer blades and screens.

Liyang Iklay Machinery Co., Ltd. is a professional manufacturer and supplier specialized in designing, manufacturing, installing and commissioning: Poultry&livestock&aqua feed production line, Biomass pellet production line, Cat litter production line; Spare parts for hammer mill& pellet mill, such as ring dies, rollers, hammer blades and screens. Our main products include precleaner, hammer mill, mixer, pellet mill, cooler, screener, automatic packing machine other auxililary equipments and spare parts etc. We have more than 10 years rich experience in the field.

We have been committed to providing customers with valuable services and high-quality products to satisfy your needs. It is for this reason that we have become a reliable and long time partner for our customer. Looking forward to our cooperation and realize win-win.