Basic Info.

Model NO.

SS series

Material

Nylon

Material Feature

Oil Resistant, Heat Resistant, Fire Resistant

Application

Food and Beverage Industry

Condition

New

Inside Material

Nylon

Feature

Oil-Resistant, Acid and Alkali Resistant

Tensile Strength

Strong

Type

Conveyor Chain

Chain Material

Plastic SUS304

Power

0.37kw

Core Components

Motor

Voltage

380V

Dimension(L*W*H)

Customized Size

Transport Package

Wooden Case

Specification

CE, ISO, UL

Trademark

LiDLi

Origin

Jiangsu

HS Code

8422309090

Production Capacity

10000meter/Month

Packaging & Delivery

Package Size

600.00cm * 300.00cm * 550.00cm

Package Gross Weight

5000.000kg

Product Description

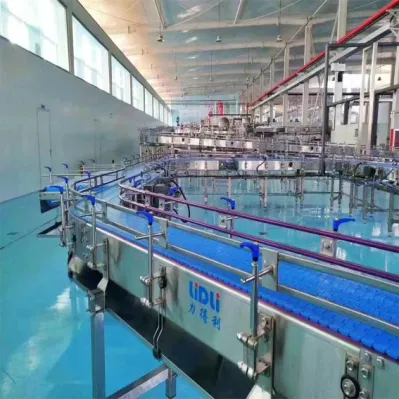

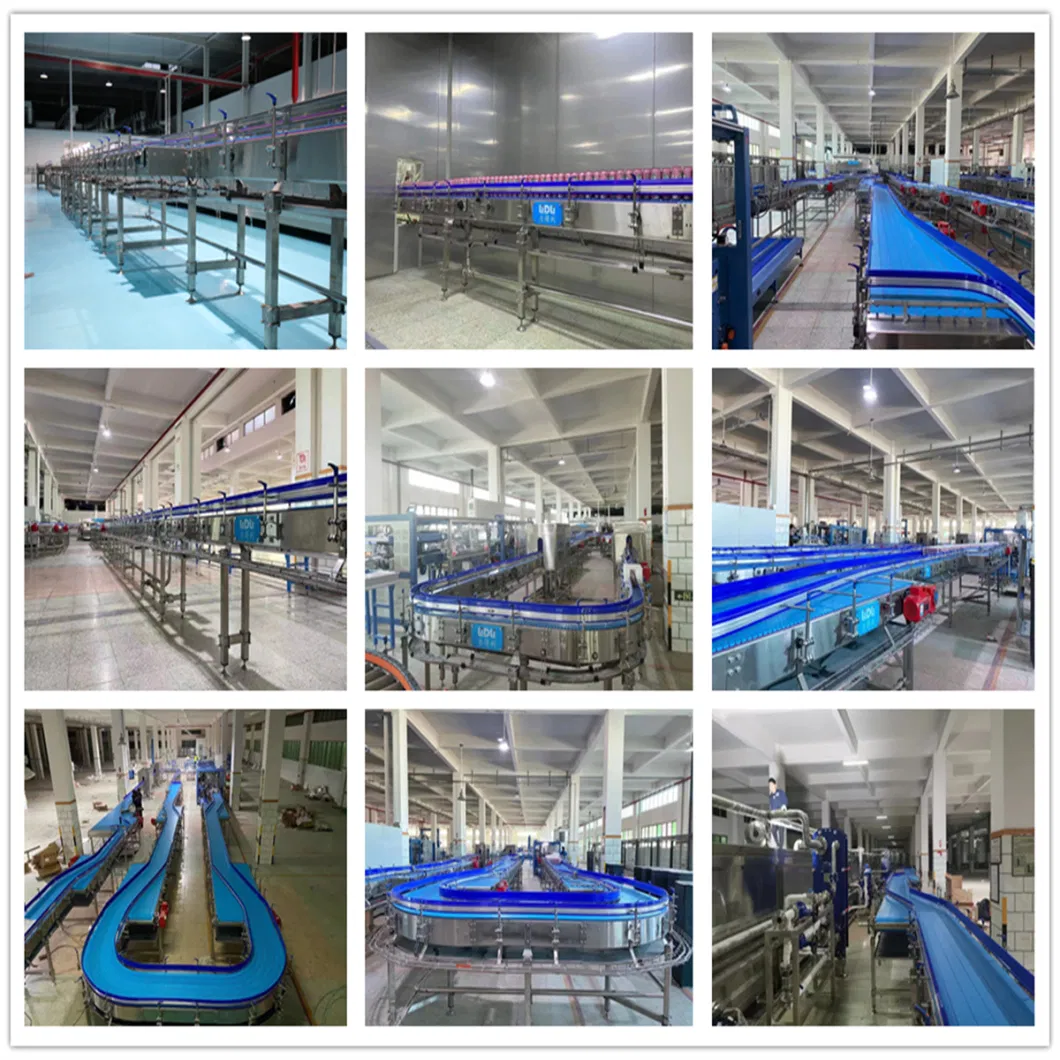

Conveyor System

The efficiency of the production line has a great relationship with the configuration of the conveyor line. When configuring the conveyor line, it must be taken into consideration that the short-term shutdown of the downstream equipment (such as replacing tags, etc.) will not affect the operation of the upstream equipment. At the same time, it should be able to well connect the equipment in the upstream and downstream sections so that the entire production line can achieve high operating efficiency.

The efficiency of the production line has a great relationship with the configuration of the conveyor line. When configuring the conveyor line, it must be taken into consideration that the short-term shutdown of the downstream equipment (such as replacing tags, etc.) will not affect the operation of the upstream equipment. At the same time, it should be able to well connect the equipment in the upstream and downstream sections so that the entire production line can achieve high operating efficiency.

The modular design has been used for the conveyor belt structure, which is compact, low-noise, and convenient in installation and maintenance. It is easy to replace the components. It is flexible to combine each part together according to different capabilities, bottle types. The electrical control design is advanced and reasonable. The control method can be designed according to the customer's floor plan requirements, and the required electrical control elements can be selected to further improve the smoothness of the delivery.

Conveyor type:

Belt width: Conveyor motor: I suggest applying various speed motors. The length below are only for empty running and only for linear conveyors.

The efficiency of the production line has a great relationship with the configuration of the conveyor line. When configuring the conveyor line, it must be taken into consideration that the short-term shutdown of the downstream equipment (such as replacing tags, etc.) will not affect the operation of the upstream equipment. At the same time, it should be able to well connect the equipment in the upstream and downstream sections so that the entire production line can achieve high operating efficiency.

The efficiency of the production line has a great relationship with the configuration of the conveyor line. When configuring the conveyor line, it must be taken into consideration that the short-term shutdown of the downstream equipment (such as replacing tags, etc.) will not affect the operation of the upstream equipment. At the same time, it should be able to well connect the equipment in the upstream and downstream sections so that the entire production line can achieve high operating efficiency. The modular design has been used for the conveyor belt structure, which is compact, low-noise, and convenient in installation and maintenance. It is easy to replace the components. It is flexible to combine each part together according to different capabilities, bottle types. The electrical control design is advanced and reasonable. The control method can be designed according to the customer's floor plan requirements, and the required electrical control elements can be selected to further improve the smoothness of the delivery.

Conveyor type:

- Linear conveyor

- Turn conveyor

- Climbing conveyor

- Multi-rows conveyor

- Accumulation conveyor

- Customize

| Belt | Engineering plastic |

| Stainless steel 304 | |

| Frame | Stainless steel 202 |

| Support | Stainless steel 202 |

| Engineering plastic |

Belt width:

- 63.5mm

- 82.6mm

- 88.9mm

- 101.6mm

- 114.3mm

- 152.4mm

- 190.5mm

- Customize

| 0.37kw | 7m |

| 0.55kw | 8-10m |

| 0.75kw | 12m |