Basic Info.

Model NO.

SS Series

Condition

New

Capacity

8000m/Per Month

Chain

Chain Board

Usage

Conveyor Chain

Feature

Oil Resistant

Surface Treatment

Oxygenation

Air Conveory

Conveyor Belt

Conveyor Speed

Adjustable

Power

0.37kw

Tensile Strength

Strong

Inside Material

Nylon

Voltage

380V

Core Components

Motor

Type

Conveyor Chain

Transport Package

Wooden Carton

Specification

customized

Trademark

HY-FILLING

Origin

China

HS Code

8422303090

Product Description

A. Empty/Filled Bottle Conveyor

Product Description

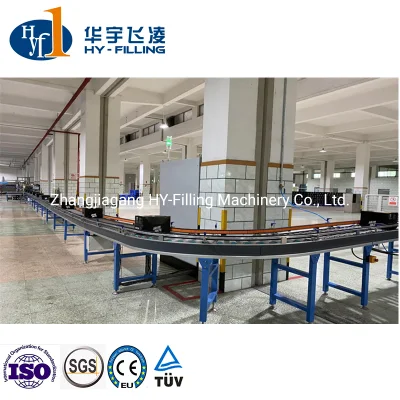

The efficiency of the production line has a great relationship with the configuration of the conveyor line. When configuring the conveyor line, it must be taken into consideration that the short-term shutdown of the downstream equipment (such as replacing tags, etc.) will not affect the operation of the upstream equipment. At the same time, it should be able to well connect the equipment in the upstream and downstream sections so that the entire production line can achieve high operating efficiency.

The modular design has been used for the conveyor belt structure, which is compact, low-noise, and convenient in installation and maintenance. It is easy to replace the components. It is flexible to combine each part together according to different capabilities, bottle types. The electrical control design is advanced and reasonable. The control method can be designed according to the customer's floor plan requirements, and the required electrical control elements can be selected to further improve the smoothness of the delivery.

Conveyor type:

Belt material:

Belt width:

B. Air Conveyor System

Product Description

Air conveyor is supported with horses on the ground, with air fan installed above the conveyor. Air filter is installed in the door of every fan, to avoid dust blown into bottles. Bottles are retained by neck supporting carrier plate in the conveyor, and transported into filling monoblock.

Main features:

1. All are made of stainless steel SUS304, except some parts as plastic and nylon made horses and supporting carrier plate.

2. Air filter is installed in the door of every fan, to avoid dust blown into bottles.

3. Bottle infeed port is equipped with bottle-block elimination device driven by hydraulic cylinder, which will remove blocked bottles automatically to prevent damage of unscrambler.

4. Bottle infeed end is equipped with two sets of photocell switches, when bottles are arranged to the first set of switches, unscrambler run from high speed to moderate speed; when bottles are arranged to the second set of switches, unscrambler stops. When bottles leave away from second set of switches, unscrambler starts and keeps running at moderate speed; when bottles leave away from first set of switches, unscrambler speed to the designed from moderate and keeps running at moderate speed.

We provide the Complete turnkey project for beverage production line includes:

Auxiliary Machines

Product Description

The efficiency of the production line has a great relationship with the configuration of the conveyor line. When configuring the conveyor line, it must be taken into consideration that the short-term shutdown of the downstream equipment (such as replacing tags, etc.) will not affect the operation of the upstream equipment. At the same time, it should be able to well connect the equipment in the upstream and downstream sections so that the entire production line can achieve high operating efficiency.

The modular design has been used for the conveyor belt structure, which is compact, low-noise, and convenient in installation and maintenance. It is easy to replace the components. It is flexible to combine each part together according to different capabilities, bottle types. The electrical control design is advanced and reasonable. The control method can be designed according to the customer's floor plan requirements, and the required electrical control elements can be selected to further improve the smoothness of the delivery.

Conveyor type:

- Linear conveyor

- Turn conveyor

- Climbing conveyor

- Multi-rows conveyor

- Accumulation conveyor

- Customize

Belt material:

| Belt | Engineering plastic |

| Stainless steel 304 | |

| Frame | Stainless steel 202 |

| Support | Stainless steel 202 |

| Engineering plastic |

Belt width:

- 63.5mm

- 82.6mm

- 88.9mm

- 101.6mm

- 114.3mm

- 152.4mm

- 190.5mm

- Customize

B. Air Conveyor System

Product Description

Air conveyor is supported with horses on the ground, with air fan installed above the conveyor. Air filter is installed in the door of every fan, to avoid dust blown into bottles. Bottles are retained by neck supporting carrier plate in the conveyor, and transported into filling monoblock.

Main features:

1. All are made of stainless steel SUS304, except some parts as plastic and nylon made horses and supporting carrier plate.

2. Air filter is installed in the door of every fan, to avoid dust blown into bottles.

3. Bottle infeed port is equipped with bottle-block elimination device driven by hydraulic cylinder, which will remove blocked bottles automatically to prevent damage of unscrambler.

4. Bottle infeed end is equipped with two sets of photocell switches, when bottles are arranged to the first set of switches, unscrambler run from high speed to moderate speed; when bottles are arranged to the second set of switches, unscrambler stops. When bottles leave away from second set of switches, unscrambler starts and keeps running at moderate speed; when bottles leave away from first set of switches, unscrambler speed to the designed from moderate and keeps running at moderate speed.

We provide the Complete turnkey project for beverage production line includes:

- Water Treatment System (Water Filtration)

- Preparation/Processing System (Mixing System for Drinks like CSD, juice etc)

- Injection molding machines (for pet preform)

- Bottle Blowing Machine (Making plastic bottles)

- Air Conveyor (Transport empty bottles)

- Filling Machine (Filling product into bottles)

- Cap elevator (Transport cap)

- Blow dryer (Blow away water drops)

- Flat Convey (Transport bottle)

- Code Printer (Printing the date on the filled bottle)

- Labeling Machine (Labeling for filled bottle)

- Bottle Packing Machine (package the filled bottles)

- Palletizing Machine (to palletize the cartons)

Auxiliary Machines

| 1.Water treatment Water treatment is equipped for pure water, mineral water, and water used in beverage drink. It contains RO, natrium filter, ultra filter, activated carbon filter, ion exchanger, ozone processor etc. |

| 2.Bottle Blowing Machine Divided into: semi-automatic bottle blowing and full automatic bottle blowing machine. Suitable for: PET bottle. Bottle size: 500ml-2L |  |

| 3.Filling Machine The machine is combined with rinsing, filling and capping, which special designed for PET bottled. It is stable characteristic, advanced technology, nice appearance and complete function. |

| 4.Filled Bottle Conveyor System Conveying belt is designed by module, component can be interchanged easily, structure is compact, noise is little, easy assembling and maintaining, have flexibility to combine the bottle type according to the different capacity. |  |

| 5.Packaging System Customized: Sleeving Label Machine, Film Shrink-wrapping Machine, Palletizing machine, Date code printer etc. |