Basic Info.

Engagement System

Full Intermeshing

Screw Channel Structure

Deep Screw

Exhaust

Exhaust

Automation

Automatic

Computerized

Non-Computerized

Capacity

120kg/H

Total Power

30kw

Real Consumption of Electricity

7-8kw

Max Size of Eraser

Diameter 50mm

Suitable Material

PVC and TPR Granule

Max Color

6

Screw Diameter

90mm

Screw Length

1800mm

Barrel Cooling Way

Water Cooling+ Air Cooling

Transport Package

in Nude or Wooden Case

Specification

10m (L)*2.5m (W)

Trademark

CANDID

Origin

China

HS Code

84633000

Product Description

CANDID automatic single color eraser making machine with stationery machine

Descriptions:

This machine is used for making TPR and PVC erasers which are commonly used in school and office, there are many kinds of erasers like single color, multicolor, heat transfer printing and carton erasers, we are capable to customize the machine producing all these different type erasers as per customer request, our machine capacity could reach 120kg/h which is very efficient.

Regarding the process, first prepare dry raw material (TPR/ PVC granular), pour the raw material into the hopper, the screw inside will do compression and grind job, simultaneously the barrel is heating the granule and make them into melting state. Then screw will press and extruding the melting granule out, pass through the water cooling channel and after cutting become the final erasers. Besides this, there are some auxiliary steps like printing logo and packing, however, for the whole process, it is very easy to handle as our machine is very automatic. Meanwhile, it does not need a big place and no matter man or women could both handle this job as it does not need heavy labor for all the work. To sum up, this is an ideal investment and we are most professional in this field and will fully support our customer.

Advantages

1. Candid eraser making machine Heating ring use cast aluminum

2. We especially installed the Heating ring heat protection cover

3. Candid eraser making machine is used TWIDEC (Tai wan) temperature control device

4. We use international band inverter like SANKEN/HITACHI

5. Cover shell: stainless steel

6. Barrel heating zones: 4

7. Cooling way: Water cooling+ Air cooling

Technical parameter

FAQ

Q: What is the raw material for eraser?

A: The raw material for eraser is PVC or TPR granule.

Q: Can you supply raw material?

A: Yes, we can supply raw material with different grade.

Q: What is electrical supply of machine?

A: Our machine normally is 380V, 3P, 50Hz, but it could be as your requirement.

Q: Could one set of machine make all color eraser?

A: No, single color machine for single color eraser; Multiple color machine for multiple color eraser.

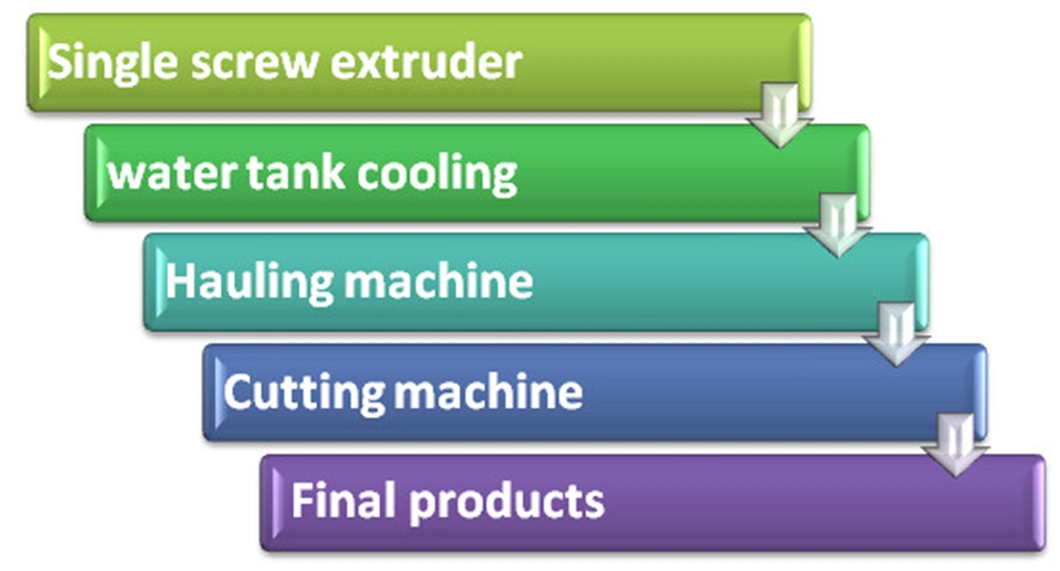

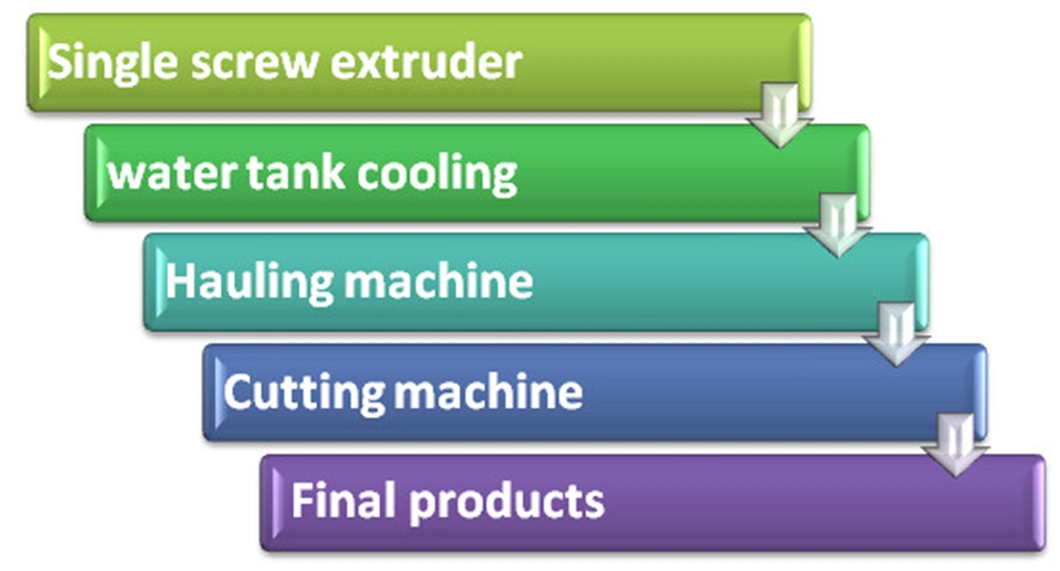

Q: What is eraser making machine woking progress?

A: The progress as blow: Raw material >> Extruding>> Cooling>>Hauling>>Cutting>>Packing>>Eraser

Q: What is the power of eraser making machine?

A: Our eraser making machine is with different power, please refer to our quotation.

Process

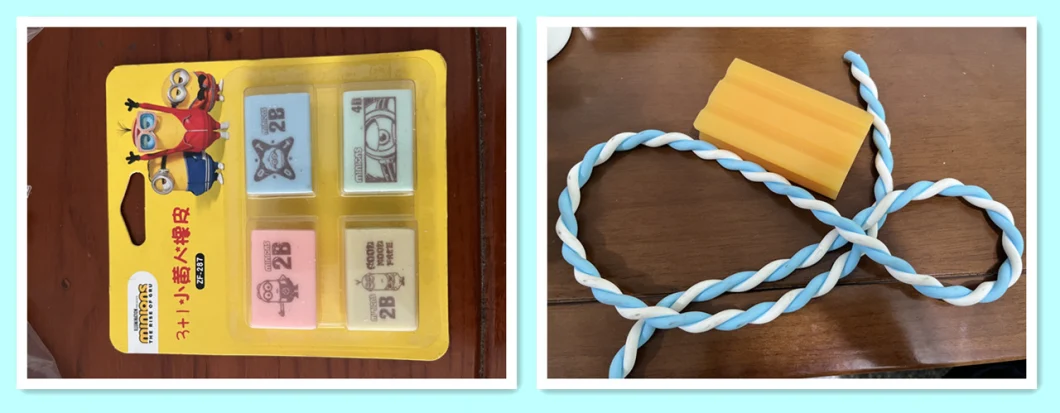

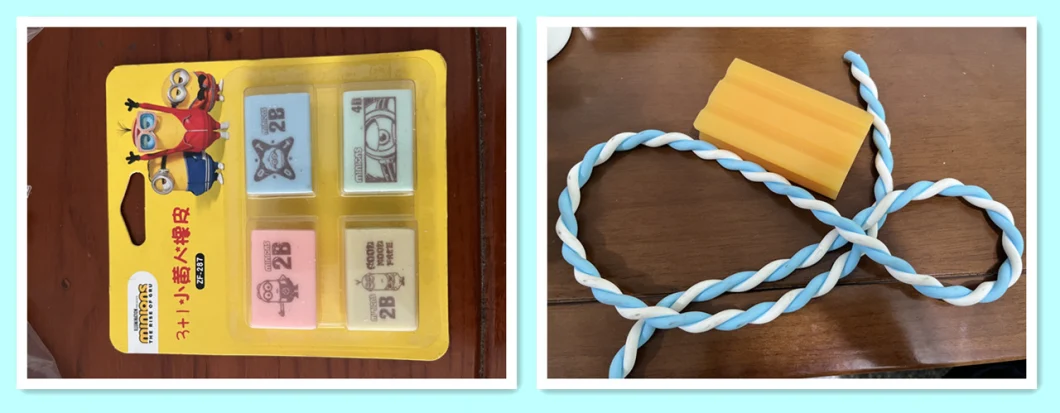

Product show

Details

Finish product

Packing and loading container

Descriptions:

This machine is used for making TPR and PVC erasers which are commonly used in school and office, there are many kinds of erasers like single color, multicolor, heat transfer printing and carton erasers, we are capable to customize the machine producing all these different type erasers as per customer request, our machine capacity could reach 120kg/h which is very efficient.

Regarding the process, first prepare dry raw material (TPR/ PVC granular), pour the raw material into the hopper, the screw inside will do compression and grind job, simultaneously the barrel is heating the granule and make them into melting state. Then screw will press and extruding the melting granule out, pass through the water cooling channel and after cutting become the final erasers. Besides this, there are some auxiliary steps like printing logo and packing, however, for the whole process, it is very easy to handle as our machine is very automatic. Meanwhile, it does not need a big place and no matter man or women could both handle this job as it does not need heavy labor for all the work. To sum up, this is an ideal investment and we are most professional in this field and will fully support our customer.

Advantages

1. Candid eraser making machine Heating ring use cast aluminum

2. We especially installed the Heating ring heat protection cover

3. Candid eraser making machine is used TWIDEC (Tai wan) temperature control device

4. We use international band inverter like SANKEN/HITACHI

5. Cover shell: stainless steel

6. Barrel heating zones: 4

7. Cooling way: Water cooling+ Air cooling

Technical parameter

Output | 120kg/h |

Screw quantity | 1 |

Barrel heating zones | 4 |

Heating power | 15kg |

Motor power | 11kw |

Barrel cooling way | Water +air cooling |

Temperature control | 0-110ºC |

Current source | 380V 3P 50Hz |

Size of water cooling channel | 400*380*800mm |

Hauling-off speed | Max 700m/h |

FAQ

Q: What is the raw material for eraser?

A: The raw material for eraser is PVC or TPR granule.

Q: Can you supply raw material?

A: Yes, we can supply raw material with different grade.

Q: What is electrical supply of machine?

A: Our machine normally is 380V, 3P, 50Hz, but it could be as your requirement.

Q: Could one set of machine make all color eraser?

A: No, single color machine for single color eraser; Multiple color machine for multiple color eraser.

Q: What is eraser making machine woking progress?

A: The progress as blow: Raw material >> Extruding>> Cooling>>Hauling>>Cutting>>Packing>>Eraser

Q: What is the power of eraser making machine?

A: Our eraser making machine is with different power, please refer to our quotation.

Process

Product show

Details

Finish product

Packing and loading container