Basic Info.

Model NO.

HKJ250

Applicable Materials Shape

Powder

Colour

Selected

Cetificate

Ce

Material

All Kinds of Crops

Animal Feed

Pellet Mill

Transport Package

iron sheet box

Specification

CE ISO SGS

Trademark

Yulong

Origin

Shandong, China

HS Code

84793000

Production Capacity

60sets/month

Product Description

HKJ250 Animal Feed Pellet Mill

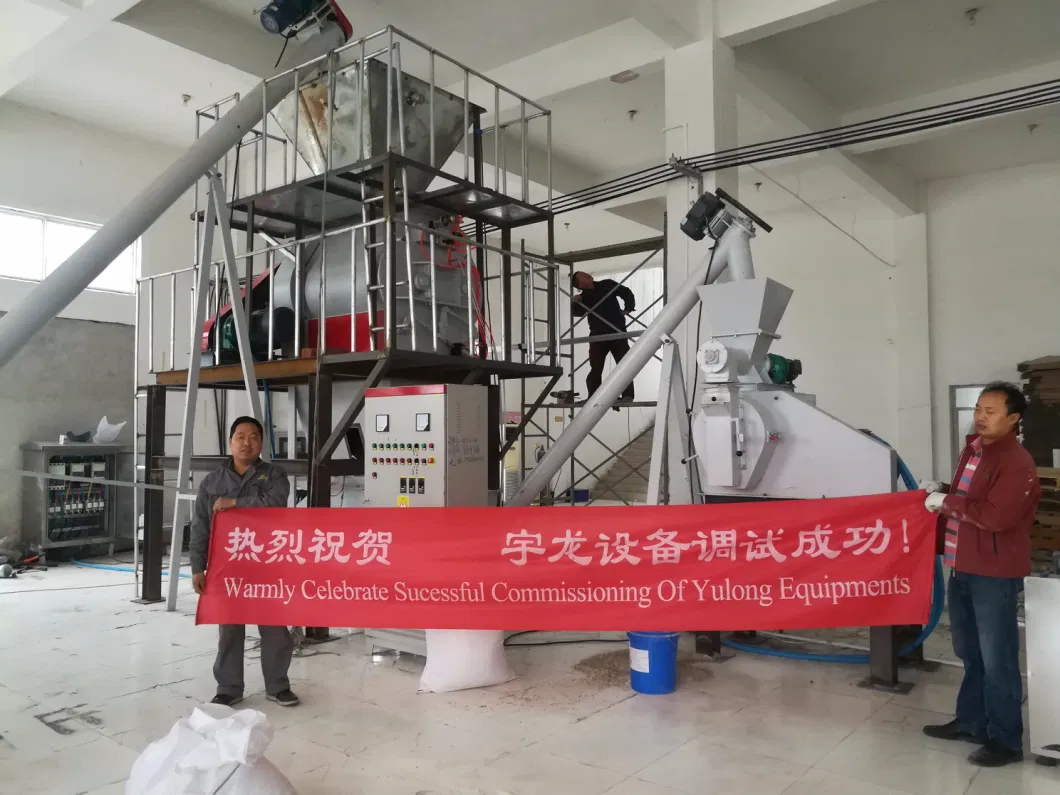

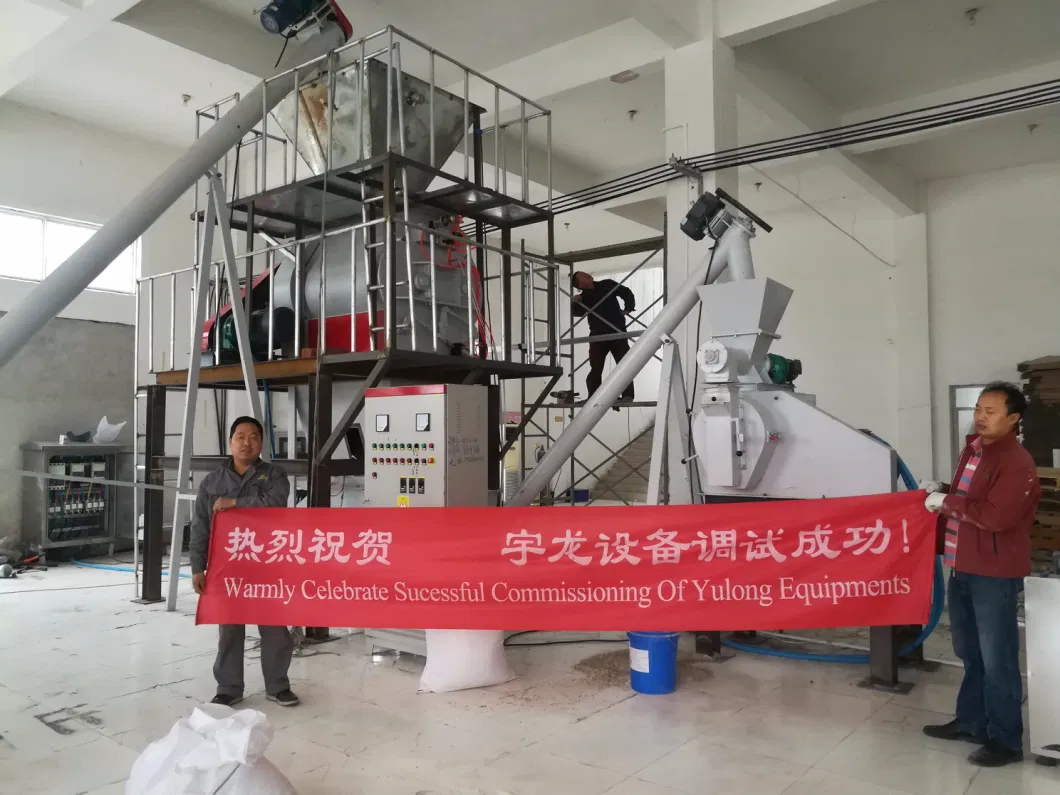

1. We are the special pellet machine manufacturer and got CE ISO9001 certificate for 15Years, In this industry, we have the rich experience. We can offer the single pellet machine And pellet production line. Our main products include: Hammer mill, pellet machine, wood Chipper, sawdust machine, screener, cooling and drying equipment.

2. The feed granulator machine use of forced feeding and overload protection device, even And nothing hinders. Low noise, make sure the machine work more safer and reliable.

3. The feed granulator adopts the big diameter conditioner, make the raw material slaking Fully, pellets are more smoother, the hardness is more medium, the formation reach 98%,The wear rate ring die has been fallen to be bottom.

4. The feed granulator adopt speed-adjust feeding, it can control the feeding capacity

Correctly to fit for different materials, meet for the production requirement of pellets with Different diameters.

5. The feed granulator Key spare parts are made by CNC system, which can ensure machineHigh precision and quality. Our products got the CE certificate, this certificate not only our Machine quality prove, but also the customer give our strong support.

6. We have the different models feed granulator, they can meet the different requirements of Customers on the yield need.

7. If you are interested in our feed granulator machine, please kindly let us know

More information.

1. How many kinds of materials and what are they?

2. What is the size and moisture content of your raw materials?

3. What's capacity(t/h) you want?

1. We are the special pellet machine manufacturer and got CE ISO9001 certificate for 15Years, In this industry, we have the rich experience. We can offer the single pellet machine And pellet production line. Our main products include: Hammer mill, pellet machine, wood Chipper, sawdust machine, screener, cooling and drying equipment.

2. The feed granulator machine use of forced feeding and overload protection device, even And nothing hinders. Low noise, make sure the machine work more safer and reliable.

3. The feed granulator adopts the big diameter conditioner, make the raw material slaking Fully, pellets are more smoother, the hardness is more medium, the formation reach 98%,The wear rate ring die has been fallen to be bottom.

4. The feed granulator adopt speed-adjust feeding, it can control the feeding capacity

Correctly to fit for different materials, meet for the production requirement of pellets with Different diameters.

5. The feed granulator Key spare parts are made by CNC system, which can ensure machineHigh precision and quality. Our products got the CE certificate, this certificate not only our Machine quality prove, but also the customer give our strong support.

6. We have the different models feed granulator, they can meet the different requirements of Customers on the yield need.

7. If you are interested in our feed granulator machine, please kindly let us know

More information.

1. How many kinds of materials and what are they?

2. What is the size and moisture content of your raw materials?

3. What's capacity(t/h) you want?

| Parameter | HKJ 250 | HKJ 300 | HKJ 350 | HKJ 450-A | HKJ 450-B | HKJ610 |

| Capacity(t/h) | 0.5-1.5 | 1-3 | 3-5 | 4-6 | 5-8 | 7-12 |

| Power of main motor(kw) | 22 | 37-45 | 2×30(55) | 45×2 | 110 | 150 |

| Power of feeder(kw) | 0.55 | 0.75 | 0.75 | 1.5 | ||

| Power of conditioner(kw) | 2.2 | 2.2 | 3 | 5.5 | ||

| Inner dia of die(mm) | Φ250 | Φ300 | Φ350 | Φ450 | ||

| Rotate speed of die(mm) | 348 | 348 | 348 | 348 | ||

| Quantity of rollers | 2 | 2 | 2 | 2 | ||

| Out dia of die(mm) | Φ103 | Φ132 | Φ160 | Φ204 | ||

| Rotate speed of feeder(r/min) | 12-120 | |||||

| Rotate speed of feeder(r/min) | 350 | |||||

| Pellet spec(mm) | Φ1.5,Φ2,Φ2.5,Φ3,Φ3.5,Φ4,Φ4.5,Φ5,Φ6,Φ8,Φ10,Φ12 | |||||

| Pressure of steam(mpa) | 0.1-0.4 | |||||

| Steam using(t/h) | ≥0.3 | |||||

| Temperature of steam | 130-150 | |||||