Basic Info.

Controlling Mode

CNC

Energy Saving

Energy Saving

Certification

CE

Warranty

5 Years

Customized

Customized

Condition

New

Color

Multi Color

After-sales Service

Remote Video Guidance

Package

Standard Wooden Package

Transport Package

Wooden Case Packing

Trademark

GATE

Origin

China

Production Capacity

3-10t/H

Packaging & Delivery

Package Size

300.00cm * 160.00cm * 200.00cm

Package Gross Weight

500.000kg

Product Description

Horizontal Ring Die Pellet Machine

Product Advantage

Scope Of Use

Horizontal ring die pellet machine is widely used in large, medium and small aquaculture, food and feed processing plants, livestock farms, poultry farms, individual farmers and small and medium-sized farms, farmers or large, medium and small feed processing plants.It is also suitable for pressing granules such as breeding plants, fertilizer plants, Chinese herbal medicines, chemical industry, etc., and can be applied with various powdery materials.

Horizontal ring die pellet machine is widely used in large, medium and small aquaculture, food and feed processing plants, livestock farms, poultry farms, individual farmers and small and medium-sized farms, farmers or large, medium and small feed processing plants.It is also suitable for pressing granules such as breeding plants, fertilizer plants, Chinese herbal medicines, chemical industry, etc., and can be applied with various powdery materials.

Pelletizing Type

Horizontal ring die granulator is a machine that makes the corresponding raw materials into the required pellets. Rice husks, corn, soybean meal, straw, grass and other materials can be made into required granular products.

Horizontal ring die granulator is a machine that makes the corresponding raw materials into the required pellets. Rice husks, corn, soybean meal, straw, grass and other materials can be made into required granular products.

Product Mix

1. The main drive adopts high-precision gear transmission, and the output is increased by about 20% compared with the belt transmission type.

2. Imported high-quality bearings and oil seals are selected to ensure efficient, stable and low noise operation of the whole machine.

3. A variety of aperture ring die for selection, process ring die, long service life, smooth granulation, high quality.

4. It adopts the international advanced level, with novel structure, compact, safety, low noise and low fault performance.

1. The main drive adopts high-precision gear transmission, and the output is increased by about 20% compared with the belt transmission type.

2. Imported high-quality bearings and oil seals are selected to ensure efficient, stable and low noise operation of the whole machine.

3. A variety of aperture ring die for selection, process ring die, long service life, smooth granulation, high quality.

4. It adopts the international advanced level, with novel structure, compact, safety, low noise and low fault performance.

Working Principle

The horizontal ring die granulator is placed horizontally, and the raw materials fall to the bottom of the ring die from top to bottom, and then granulate at 90 degrees. The mold rotates, the auxiliary roller rotates forcefully, and the particles follow the rotation in the mold during the high-speed rotation process, resulting in the particles being easily crushed.

The horizontal ring die granulator is placed horizontally, and the raw materials fall to the bottom of the ring die from top to bottom, and then granulate at 90 degrees. The mold rotates, the auxiliary roller rotates forcefully, and the particles follow the rotation in the mold during the high-speed rotation process, resulting in the particles being easily crushed.

What Can I Do For You

Pre-sale

Our account manager will communicate with you the product requirements related to your machine.

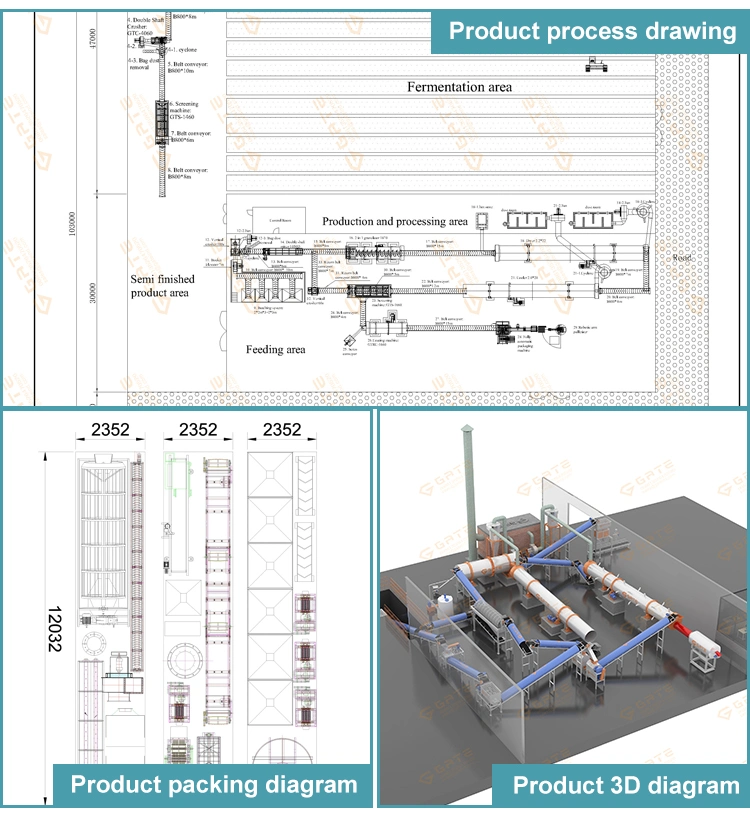

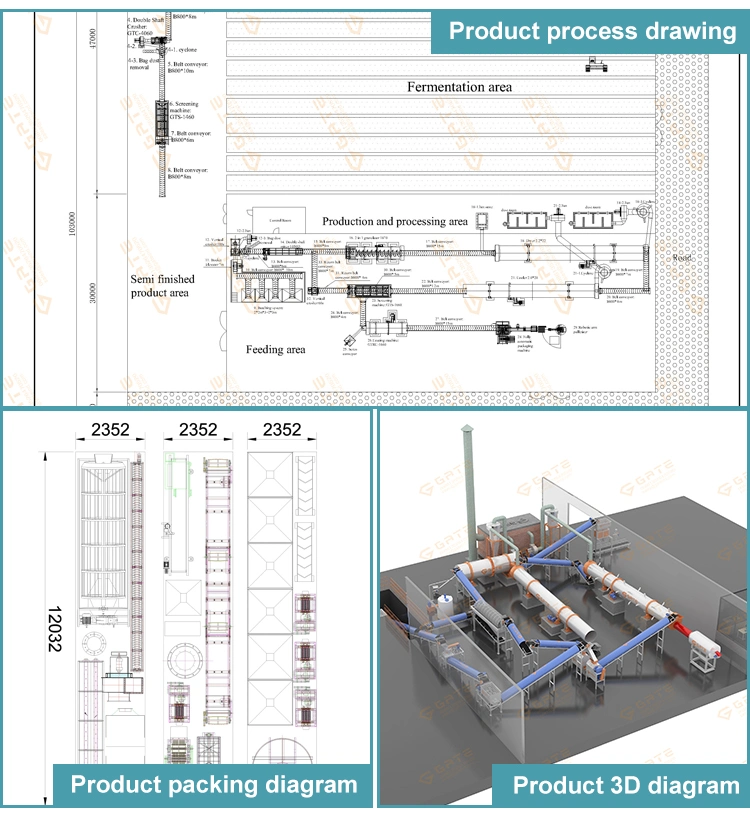

We offer free product plans, packaging drawings and 3D renderings to save your budget.

We will provide our own quotation and proof of our machines.

We have a professional R & D department, to provide you with the most professional technical support. We can make granulation experiment according to your raw materials.

Our account manager will communicate with you the product requirements related to your machine.

We offer free product plans, packaging drawings and 3D renderings to save your budget.

We will provide our own quotation and proof of our machines.

We have a professional R & D department, to provide you with the most professional technical support. We can make granulation experiment according to your raw materials.

On sale

During the production of the equipment, we will feed back the production progress to you. We support customer on-site inspection, video inspection, third party inspection, factory inspection agency inspection. We can provide certificate of origin, customs clearance and other certificates. We offer you a free test service before the machine leaves the factory.

During the production of the equipment, we will feed back the production progress to you. We support customer on-site inspection, video inspection, third party inspection, factory inspection agency inspection. We can provide certificate of origin, customs clearance and other certificates. We offer you a free test service before the machine leaves the factory.

After sale

If you need to install, we have a professional overseas installation team We will provide you with installation drawings or a video guide for making the installation. We support to provide you with free accessories within one year of purchase of machine equipment. We will provide a five year warranty on important parts of the equipment.

If you need to install, we have a professional overseas installation team We will provide you with installation drawings or a video guide for making the installation. We support to provide you with free accessories within one year of purchase of machine equipment. We will provide a five year warranty on important parts of the equipment.

FAQ

| Q: Can I use this production line to produce multi granularity particles? |

| Yes, our production line is multifunctional. We can customize ring moulds of different sizes. In this way, you can easily adjust the size of your ball. |

| Q: I know little about the fertilizer production line. How to choose the most suitable machine? |

| Just tell us your raw materials, capacity (tons / hour) and the size of the final particle product, and we will choose the machine for you according to your specific situation. |

| Q: Our workers don't know how to operate the production line. What should I do? |

| Our engineers will instruct the site workers on how to install the machines and build the workshop.And field test the production line, training workers how to operate. |

| Q: Are you a trading company or a manufacturer? |

| We have a large factory in Jiaozuo, China, covering an area of 10000 square meters. Welcome to visit. |

| Q: What's the Production Period of the Fertilizer Machine? |

| For single fertilizer machine, our production time is 7 days;and for whole fertilizer production line, our production time is no more than 30 days. |

| Q: What's the Quality Guarantee and Certifications? |

| All of our machine have passed ISO and CE certification, we can guarantee the highest quality and our warranty time is 5 years after shipment date. |