- Overview

- Product Description

- Detailed Photos

- Product Parameters

- Application

- Related Products

- Packaging & Shipping

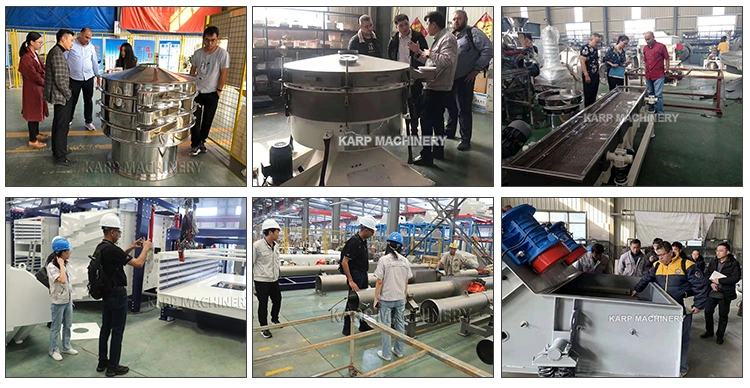

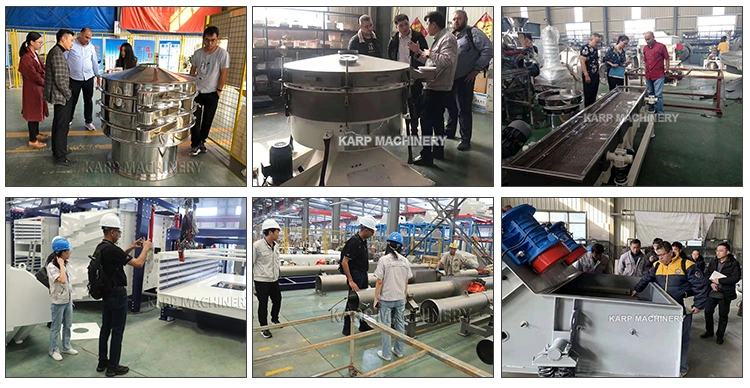

- Company Profile

- FAQ

Basic Info.

Model NO.

ZKJ

Material

Stainless Steel

Material Feature

Heat Resistant, Fire Resistant

Application

Chemical Industry, Food Industry

Condition

New

Hopper Volume

12-90L

Length of Conveying

up to 30 Meters

Height of Discharge

up to 20 Meters

Capacity

0.05 T/H - 6 T/H

Noise

Below 75dB

Standard

Accordance with GMP

Voltage

380V / Custom

Transport Package

Standard Export Wooden Case

Specification

140mm-600mm

Trademark

KARP

Origin

Xinxiang City, Henan Province, China

HS Code

8428399000

Production Capacity

200 Set/Sets Per Month

Product Description

Food Processing Vacuum Powder Transport System Protein Powder Vacuum Feeder

Working principle:

The Food Processing Vacuum Powder Transport System Protein Powder Vacuum Feeder unit utilizes a vortex air pump to extract air, creating a vacuum state within the material suction nozzle and the entire system. The material is drawn into the suction tube along with the surrounding air, forming a flow of material-laden air. Subsequently, it reaches the hopper, where the separation of air and material takes place. The separated material then enters the receiving device. The feeding and discharging of materials are achieved by continuously opening and closing the pneumatic three-way valve, which is controlled by the control center.

The vacuum feeder unit is equipped with a compressed air reverse blow device. During each material discharge, compressed air pulses are used to blow off any powder adhering to the surface of the filter, ensuring the proper functioning of the material absorption process.

01

Food grade suction tube

Food grade suction tube

* Its length can be up to 30 meters.

* Metal pipe can be optional.

* Food grade pipe, more sanitary.

* Metal pipe can be optional.

* Food grade pipe, more sanitary.

02

Control panel

Control panel

* Switch on and off.

* The time of discharge and charging materials can be adjusted.

* The time of discharge and charging materials can be adjusted.

03

Quick clamp

* Help to disassembly the hopper quickly to clean or maintain it.

04

Sanitary vacuum pump trolley

Sanitary vacuum pump trolley

* Easy to move.

* Streamline your production processes.

05

Filter

* Many types of filters can be chosen, such as cloth bag film-covered filter, PE film filter, stainless steel filter, titanium filter element.

Optional filter:

Main advantages:

* Easy material aspiration and dust-free loading of machines.

* Simple installation and operation.

* Favourable investment and operating costs.

* Optimum hygiene conditions and accord with GMP standard.

| Type 1: ZKJ Vacuum conveyor with pump is equipped with manual lifting device & movable trolley, discharge height can be adjustable manually, up to 2 m. | Type 2: ZKJ Vacuum feeder with pump without lifting device, suitable discharge height above 2 m, the hopper can be placed directly above the inlet of the downstream machine. |

| Type 3: QVC Pneumatic vacuum conveyor without vacuum pump model, small space, but large air consumption. | Type 4: ZKJ Hybrid vacuum feeder can work with full enclosed mixer, such as V-type mixer, 2D/3D mixer, double-cone mixer, etc. |

| ZKJ Electric Vacuum Conveyor System | ||||

| Model | Power (KW) | Hopper Volume (L) | Air Presser (Mpa) | Capacity (kg/h) |

| ZKJ-1 | 1.5 | 12 | 0.4-0.6 | 400 |

| ZKJ-2 | 2.2 | 12 | 600 | |

| ZKJ-3 | 3.0 | 18 | 1200 | |

| ZKJ-4 | 5.5 | 40 | 2500 | |

| ZKJ-6 | 7.5 | 40 | 4000 | |

| ZKJ-7 | 7.5 | 90 | 6000 | |

| QVC Pneumatic Vacuum Feeder Conveying Machine | ||||

| Model | Air consumption (L/min) | Hopper Volume (L) | Air Presser (Mpa) | Capacity (kg/h) |

| QVC-1 | 180 | 1.1 | 0.4-0.6 | 400 |

| QVC-2 | 360 | 6 | 600 | |

| QVC-3 | 720 | 12 | 1200 | |

| QVC-4 | 1440 | 42 | 2500 | |

Note: The conveying capacity is measured when the conveying tube is 4 meters long and the conveying material is flour. The longer the conveying tube is, the lower the conveying capacity is, and the conveying capacity is also greatly related to the characteristics of the material.

Please contact us, we will choose a best suitable model according to your needs.

Vacuum conveyor feeder feeds to vibrating screen

vacuum Powder Transfer System works with bag dumping station and vibro sifter

Hybrid vacuum conveyor works with mixer

Vacuum feeder conveyor on customer onsite

Food Processing Vacuum Powder Transport System Protein Powder Vacuum Feeder uses vacuum pump as its vacuum source, which can directly feed the material from the container into the crusher, packaging machine, ribbon mixer, vibrating screen, silo, reactor, etc. You can refer to the picture above.

We provide one stop solution for powder and granules materials: screening, conveying, weighing, mixing, packing and dumping. Contact us to get more detail information.

| Round vibrating screen | Small bag dumping station | Big bag unloading station |

Packing for Food Processing Vacuum Powder Transport System Protein Powder Vacuum Feeder.

Outside package: standard export wood box.

Inner package: stretch film for machine, accessories in carton.

Inner package: stretch film for machine, accessories in carton.

Xinxiang KARP Machinery Equipment CO.,Ltd is one of the leading manufacturers of vibrating screen sifter, conveying machines, feeding machines, elevating machines and related products with 11-year designing and manufacturing experiences.

Xinxiang KARP Machinery Equipment CO.,Ltd is one of the leading manufacturers of vibrating screen sifter, conveying machines, feeding machines, elevating machines and related products with 11-year designing and manufacturing experiences.

We are committed to solve all screening and conveying problems of bulk materials. Depending on the quality as the life of enterprise, we have won our customers' identity with professional solution, high quality products, perfect service. Our main products are vibrating screen, round separator, rectangular separator, drum screen, gyratory screen, tumbler screen, screw conveyor, belt conveyor, vacuum conveyor (Food Processing Vacuum Powder Transport System Protein Powder Vacuum Feeder), vibration table, standard laboratory inspection sieve, bucket elevator, vibration elevator, vibration motor, vibrating conveyor, feeding machine and related parts.

All of our products are widely used in food, additive, lithium battery industry, chemical, metallurgy, building materials, mining, environmental protection and other fields. Warmly welcome friends from all over the worlds to our company, we look forward to sincere cooperation and mutually beneficial development with you.

Our CE certificate:

Our customers:

Our CE certificate:

Our customers:

Warmly welcome friends from all over the worlds to our company, we look forward to sincere cooperation and mutually beneficial development with you.

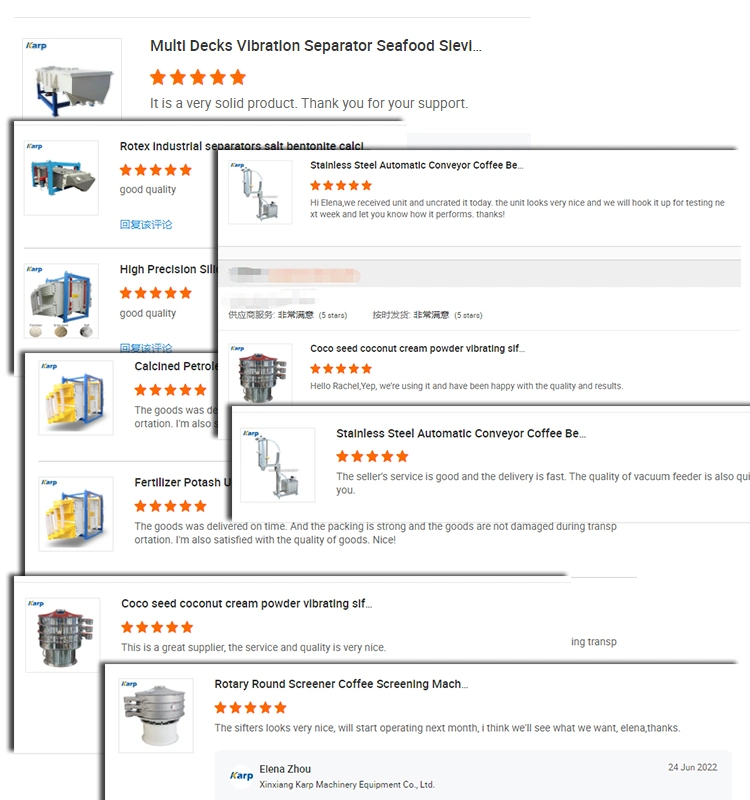

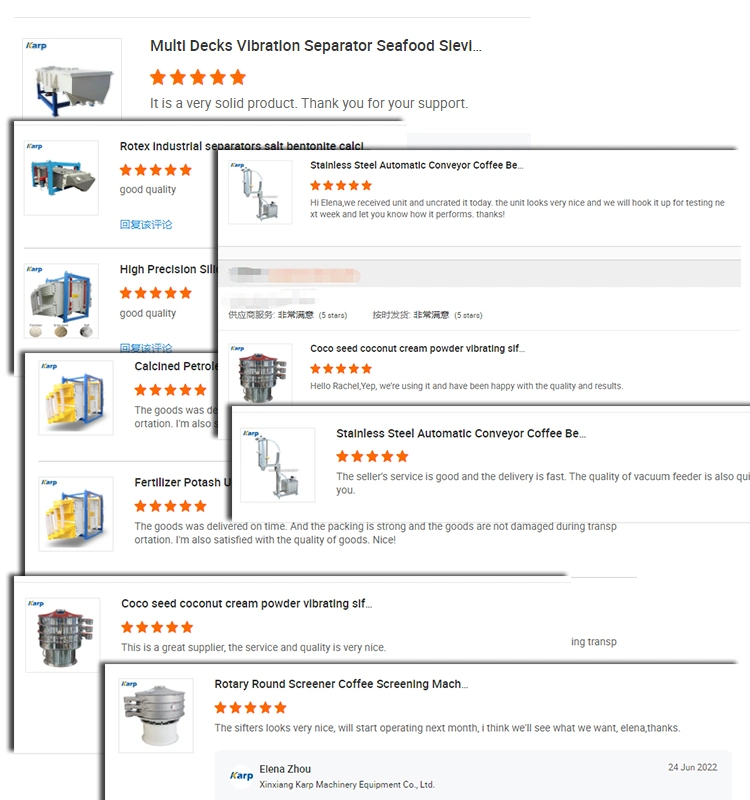

Our equipment has been widely praised:

The proper selection of the Food Processing Vacuum Powder Transport System Protein Powder Vacuum Feeder depends on the raw material, conveying length and height, discharge height, upstream and downstream equipment, capacity, etc:

1. Raw material_____? Bulk density_____?

2. What's the height of discharge_____meters?

3. Horizontal conveying length_____meters?

4. Conveying capacity per hour: _____KG/H?

5. Which equipment does the vacuum feeder suck powders from and feed to?

6. Voltage_____(V), Frequency_____(Hz), Phase_____(P)?

Q: How long for the manufacturing time?

A: 10-15 working days.

Q: How long for warranty time?

A: 13 months from the shipping date.

Q: Can your engineer come to the construction site to guide the installation?

A: Yes, we can arrange our engineer to guide your installation.

Q: How can we guarantee the quality?

A: We provide a set of the sealing parts and installation tools of vibrating screen with our machine for free. And one year warranty period.

Q: What can you buy from us?

A: We provide one stop solution for powder materials: screening, conveying, weighing, mixing, packing and dumping.

2. What's the height of discharge_____meters?

3. Horizontal conveying length_____meters?

4. Conveying capacity per hour: _____KG/H?

5. Which equipment does the vacuum feeder suck powders from and feed to?

6. Voltage_____(V), Frequency_____(Hz), Phase_____(P)?

Q: How long for the manufacturing time?

A: 10-15 working days.

Q: How long for warranty time?

A: 13 months from the shipping date.

Q: Can your engineer come to the construction site to guide the installation?

A: Yes, we can arrange our engineer to guide your installation.

Q: How can we guarantee the quality?

A: We provide a set of the sealing parts and installation tools of vibrating screen with our machine for free. And one year warranty period.

Q: What can you buy from us?

A: We provide one stop solution for powder materials: screening, conveying, weighing, mixing, packing and dumping.