- Overview

- Product Description

- Product Feature

- On-site Pictures

- Company Profile

Basic Info.

Model NO.

PL

Max Feeding (mm)

6mm

Capacity(t/h)

3-15cbm/Hour

Motor Power(kw)

20~25

Installation Slope

Customized

Chute size(mm)

Dia1000

Overall Dimension

1800*1600*2300

Conveying Distance

up to 30 Meters

Dust Filter Precision

1micron

Loading Mode

Continuous

Pipe Diameter

45mm 65mm

Material of Pipe

SUS304/SUS316/PU

Application

Moving Soybean Quinoa Into Storage Silo

Transport Package

Plywood Case

Specification

PLVC10

Trademark

COBRO TECH

Origin

China

HS Code

847410

Production Capacity

200 Sets/Month

Product Description

Automatic soybean quinoa vacuum Conveyor with storage silos and bag unloader

The vacuum conveyor system consist of roots blower,pulse dust collector,silos,bag dump station,PLC control system etc.The system is totallly full sealed and PLC controlled with the advantage of dust-free and lobor saving.The basic principle of vacuum conveyor system is to move the suspended material such as tablet,capsule in a relatively uniform stream from a feed station or supply source to a delivery point.The vacuum,generated by a vacuum pump or blower,creates a high enough air velocity and low enough solids to air ratio to effectively move the materials. Our vacuum powder transfer system ranges from PL-VC1 to PL-VC10 with capacity up to 10 tons per hour and suitable for bulk material transport in bulk bag unloading,dosing,milling,pelleting,screening and batch feeding of process tanks,mixers,and other process equipment. Technical Data Sheet as Below

Technical Data Sheet as Below | Model | Power | Air pressure | Capacity(kg/Hr) |

| PLVC-1 | 1.5 | 0.4-0.6 | 400 |

| PLVC-2 | 2.2 | 0.4-0.6 | 600 |

| PLVC-3 | 3.0 | 0.4-0.6 | 1200 |

| PLVC-4 | 5.5 | 0.4-0.6 | 2000 |

| PLVC-5 | 5.5 | 0.4-0.6 | 3500 |

| PLVC-6 | 7.5 | 0.4-0.6 | 4000 |

| PLVC-7 | 7.5 | 0.4-0.6 | 6000 |

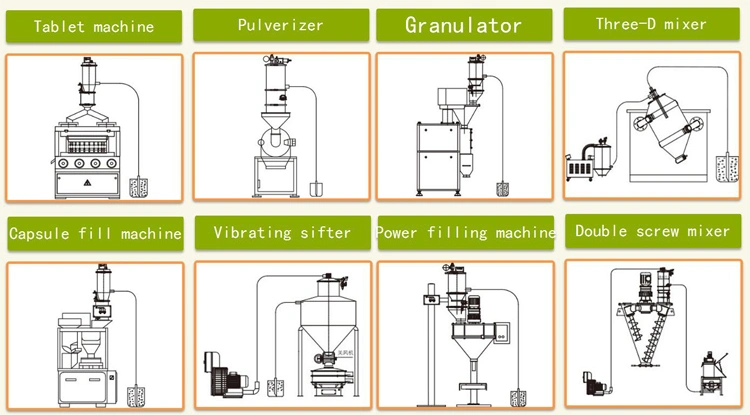

Application of Vacuum Conveyor Elevator

Main feature of vacuum conveyor system with storage silo

1.Dust free conveying and low maintenance

2.Clean easily between batches

3.Move material in any direction

4.Reduce labor cost

5.Made by SUS304 or 316L

6.No tools needed to change the filters

7.Long covneying distance

8.High screening accuracy

9.High handling rate

More Pictures