Basic Info.

Model NO.

KAF-350

Warranty

1 Year

Customized

Customized

Condition

New

Color

Multi Color

Capacity

1.3h

Innner Diameter of Ring Die

550mm

Power

90/110kw

Roller Quantity

4 PCS

Pellet Size

6/8/10/12mm

Dimension

1.9*0.95*1.8m

Weight

4500kg

Raw Material

Wood, All Kinds of Biomass Waste

Transport Package

Standard Wood Export Packaging

Specification

1.9*0.95*1.8m

Trademark

LEABON

Origin

China

Production Capacity

1000units/Month

Product Description

Sawdust waste vertical ring die wood pellet mill with CE

1. Gearbox:Continue the New generation gearbox, Driving with high-precision gears, Auto-matic Lubricant pump system keep the gearbox working stability and warranty period.

2. Vertical motor:the most characteristic is mounting hole with output shaft as the center,Equidistant distribution around, More powerful and stability of machine working.

3. Blower system:Located in one side of work bin,Free control the working time,The main function is dedusting and discharge steam.

4. Working parts:Ring-die and rollers materials are alloy steel,Heat treatment made by ourselves,Hardness more than 52,In this hardness can assure the pelleting quality and warranty time,Working manner is from inside to outside press,Centrifugal force and extrusion pressure together,Produced more capacity,At the same time assure hardness and density,The special design is 4 to 8 rollers working, Increase press rate then increase capacity,Ring-die is "vertical double-deck"structure,It can use one mold with same hole size for working life increased,Moreover it can use one mold with different hole size for saving the money for another size mold.

Advantage:

2. Vertical motor:the most characteristic is mounting hole with output shaft as the center,Equidistant distribution around, More powerful and stability of machine working.

3. Blower system:Located in one side of work bin,Free control the working time,The main function is dedusting and discharge steam.

4. Working parts:Ring-die and rollers materials are alloy steel,Heat treatment made by ourselves,Hardness more than 52,In this hardness can assure the pelleting quality and warranty time,Working manner is from inside to outside press,Centrifugal force and extrusion pressure together,Produced more capacity,At the same time assure hardness and density,The special design is 4 to 8 rollers working, Increase press rate then increase capacity,Ring-die is "vertical double-deck"structure,It can use one mold with same hole size for working life increased,Moreover it can use one mold with different hole size for saving the money for another size mold.

| SPECIFICATION FOR VERTICAL RING DIE WOOD PELLET MILL | |||||

| Model | Inner Dia of ring die | power(KW) | Capacity(ton/h) | Dimension (m) | Weight (KG) |

| LB -450MX | 450mm | 55KW | 0.8-1.0T | 1.4*0.75*1.55 | 2800 |

| LB -550MX | 550mm | 90KW | 1.5-2T | 1.9*0.95*1.8 | 4500 |

| LB -800MX | 800mm | 132KW | 2-3T | 2.5*1.35*2.1 | 7000 |

| LB-1000MX | 1000mm | 160KW | 3-4T | 2.65*1.45*2.1 | 8500 |

Advantage:

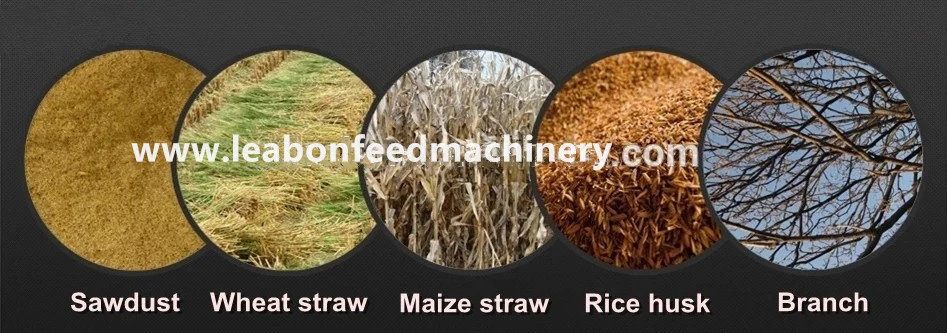

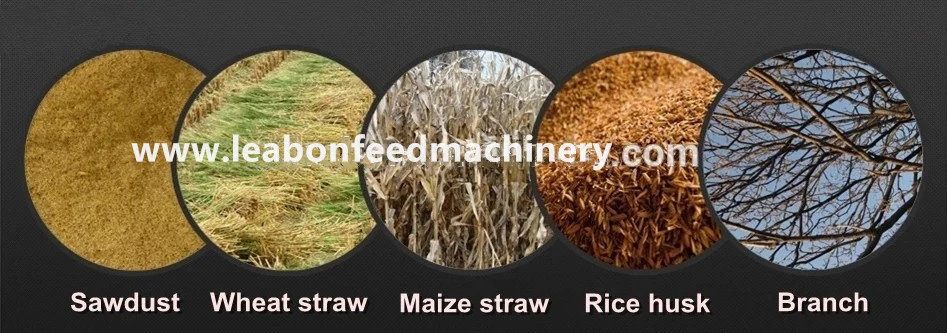

The raw material could be sawdust, wood, straw, rice husk, bagasse, cotton stalk, peanut shell, bamboo, empty fruit branch, pulverized coal, waste paper, cottonseed skins, weeds, crop stalks and other plant wastes, especially low-bonding and unformed materials.

Raw materials

Zhengzhou Leabon Feed Machinery Co., Ltd. is a professional and advanced supplier which mainly supply feed equipment like feed crusher,mixer,pellet machine,granule crumble, feed pellet cooler, packing and entire feed pellet production line. Leabon has extensive expertise in the areas of engineering. The continuous research helps us to develop the latest technology in biomass new energy field more effectively.

Raw materials

You can use all kinds of Biomass waste.

Final product

These pellets can be used in fireplace, Biomass Power Plant, etc

Other type flat die wood pellet machine:

Company Information:

Zhengzhou Leabon Feed Machinery Co., Ltd. is a professional and advanced supplier which mainly supply feed equipment like feed crusher,mixer,pellet machine,granule crumble, feed pellet cooler, packing and entire feed pellet production line. Leabon has extensive expertise in the areas of engineering. The continuous research helps us to develop the latest technology in biomass new energy field more effectively.