Basic Info.

Model NO.

GGB-80

Voltage

220V

Power

0.75KW

Customized

Customized

Model

Ggb-80

Output Size (Mesh)

50-100

Capacity(Kg/H)

70-100

Power (Kw)

4(380V/220V)

Transport Package

Standard Packaging Machine

Trademark

GG

Origin

China

HS Code

8438900000

Production Capacity

100sets/Month

Product Description

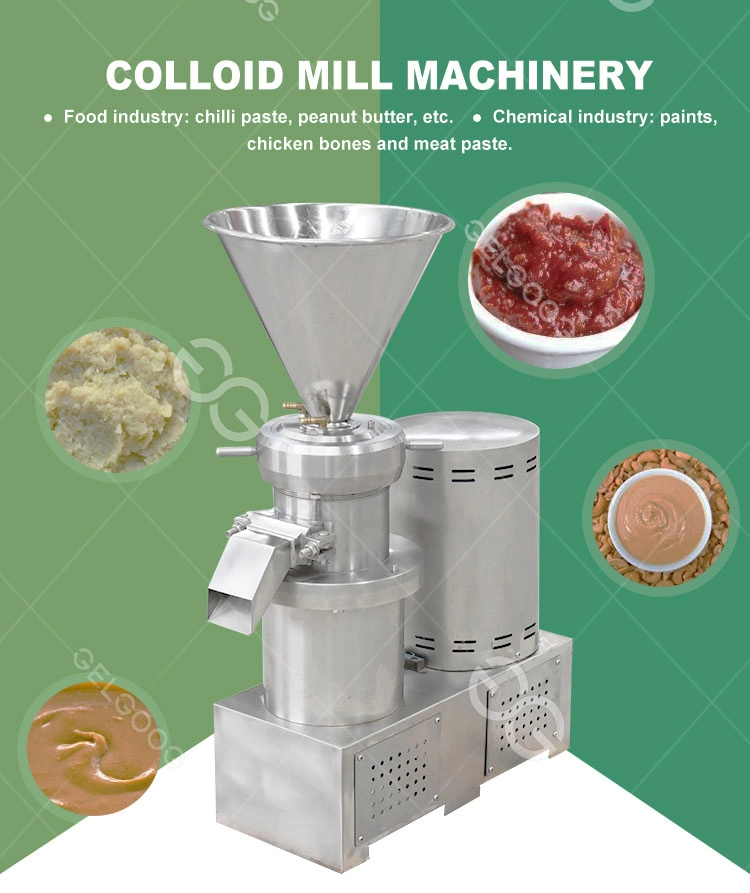

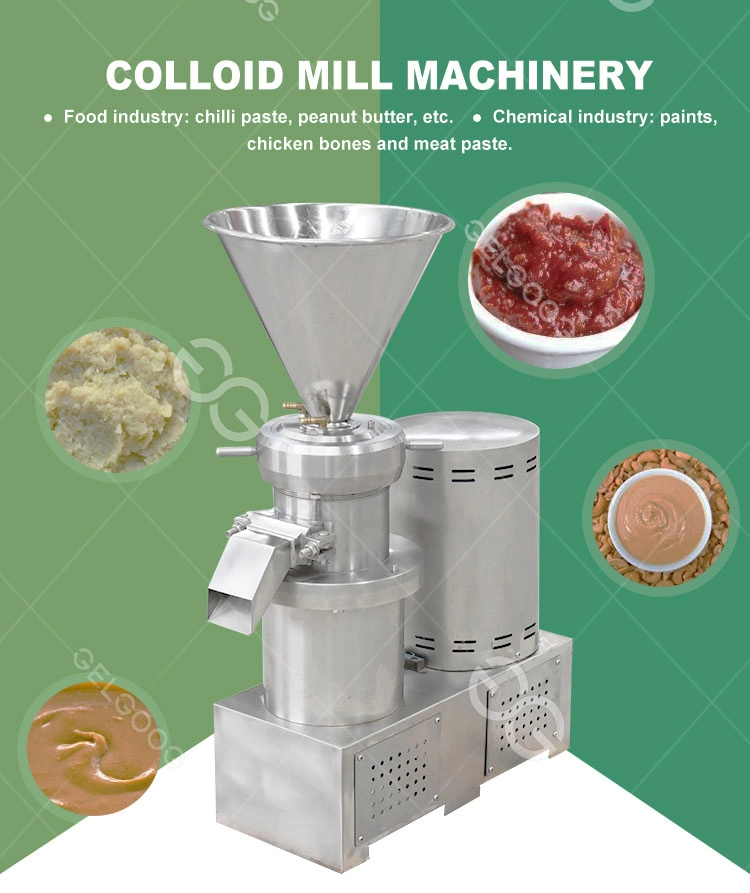

Name:Commercial Colloid Mill Machine Ginger Garlic Paste Grinding Machine Pepper Chili Sauce Colloid Mill Grinder Sauce Making Machine Garlic Paste Maker Machine

The garlic paste machine is a high-precision machine with fast running speed, line speed up to 20m/s, and extremely small gap between the grinding discs. Compared with the pressure homogenizer, the colloid mill is a centrifugal equipment first. Its advantage is simple structure and maintenance. Convenient maintenance, suitable for materials with higher viscosity and larger particles. Large processing capacity is suitable for industrialized online continuous production, which can realize automatic control, save time, high efficiency, energy saving, low noise, balanced operation, and eliminate quality differences in batch production. There are no dead ends, and the materials are completely crushed, emulsified, homogenized and mixed.

The basic principle of the garlic paste machine is that the fluid or semi-fluid material passes between the fixed tooth and the movable tooth that are relatively linked at high speed, so that the material is subjected to strong shear force, friction force and high-frequency vibration, etc., and is effectively crushed, emulsified, Homogenize and mix to obtain satisfactory finely processed products.

The garlic paste machine has various specifications such as vertical and split. The main machine part is composed of a shell, a movable grinding plate, a static grinding plate, an adjusting mechanism, a cooling mechanism, a mechanical seal, and a motor. The main parts are made of stainless steel, which is corrosion resistant. The user can select colloid mills of different specifications and models according to different material characteristics, production efficiency, and different purposes to achieve good results.

The garlic paste machine is a high-precision machine with fast running speed, line speed up to 20m/s, and extremely small gap between the grinding discs. Compared with the pressure homogenizer, the colloid mill is a centrifugal equipment first. Its advantage is simple structure and maintenance. Convenient maintenance, suitable for materials with higher viscosity and larger particles. Large processing capacity is suitable for industrialized online continuous production, which can realize automatic control, save time, high efficiency, energy saving, low noise, balanced operation, and eliminate quality differences in batch production. There are no dead ends, and the materials are completely crushed, emulsified, homogenized and mixed.

Garlic paste machine working principle:

The basic principle of the garlic paste machine is that the fluid or semi-fluid material passes between the fixed tooth and the movable tooth that are relatively linked at high speed, so that the material is subjected to strong shear force, friction force and high-frequency vibration, etc., and is effectively crushed, emulsified, Homogenize and mix to obtain satisfactory finely processed products.

Garlic paste machine Structural features:

The garlic paste machine has various specifications such as vertical and split. The main machine part is composed of a shell, a movable grinding plate, a static grinding plate, an adjusting mechanism, a cooling mechanism, a mechanical seal, and a motor. The main parts are made of stainless steel, which is corrosion resistant. The user can select colloid mills of different specifications and models according to different material characteristics, production efficiency, and different purposes to achieve good results.

Garlic paste machine Parameter

| Model | GGB-50 | GGB-80 | GGB-110 | GGB-130 | GGB-180 | GGB-240 | GGB-300 |

| Output size (mesh) | 50-100 | 50-100 | 100-200 | 100-200 | 100-200 | 100-200 | 60-200 |

| Capacity(kg/h) | 70-80 | 70-100 | 300 | 400-600 | 800-1000 | 1500-2000 | 3000-4000 |

| Power (KW) | 1.1(380V) 1.5(220V) | 4(380V/220V) | 7.5 | 15 | 18.5 | 45 | 75 |

| Weight (kg) | 50 | 150 | 175 | 285 | 340 | 1300 | 1600 |