Big Capacity Wood Branch Crushing Fuel Charcoal Briquette Sawdust Cooler Pellets Drying Packing Machinery Wood Pellet Making Production Line Product Description

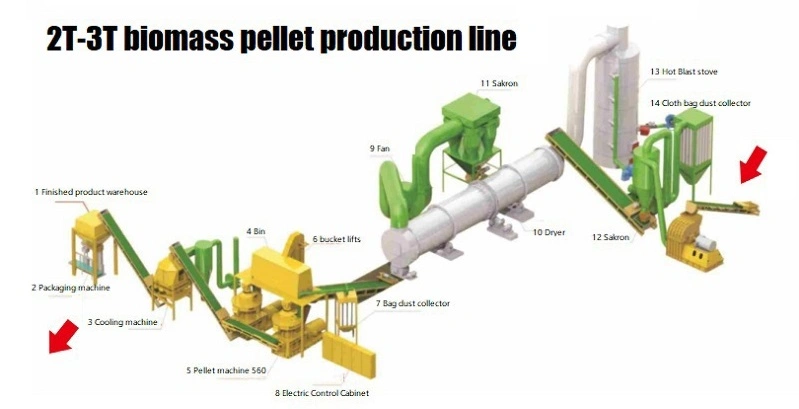

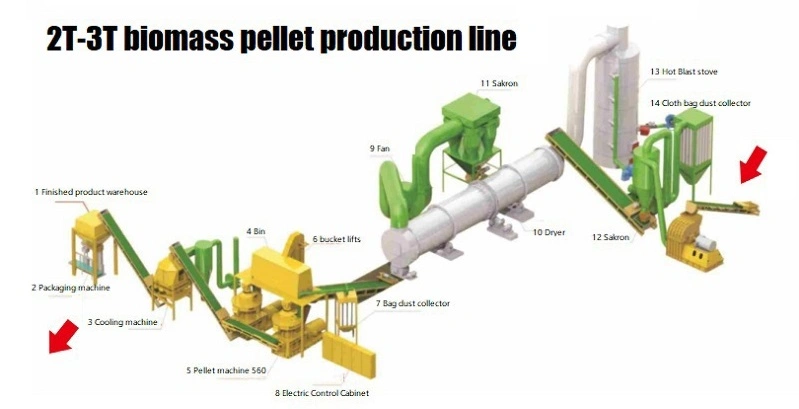

Our Wood complete set production line will crush various biomass raw materials into powder particles by the crusher , and then enter the silo/stock bin by the screw elevator. The materials in the silo are transported by the adjustable speed feeder to the granulator, the finished particles are cooled and screened by the cooling screening machine, and then enter the packaging machine through the belt conveyor. The packing machine can be set for different weight and can seal the bagging, and the whole production process is completed.

Disc chipper is a special equipment for the production of wood chips, this product is widely used in particleboard factory, medium and high density fiberboard factory, furniture factory, biomass power plant and wood chip factory. It can process wood branches, bamboo and other raw materials into sheets at one time, absorb the essence at home and abroad, use a high wear-resistant rotor, feed the raw materials directly into the machine, cut into wood chips, large output, long life.

Branch crusher is also called woodcrusher, which integrates slicing andcrushing.It can cut branches and brancheswith a diameter of 1-20cm. It is mainlyused for processing pine,miscellaneouswood, poplar. fir. raw bamboo and otherrmcteriais. It is more suitable for theprocessing of sawdust in edible fungusculture medium. At the same time,theequipment can also be used for cuttingbamboo,thatch, corn stak, sorghum stalkand other fibrous straw materials.

Biomass pellet machine known solid biomass fuels molding machine at acertain temperature and pressure,the dispersion of various types of cells,nodefinite shape after collecting biomass crops,drying, crushing,etc. Afterpretreatment, compressed into equipment rod,block or granular briquette. Themain structure is divided flat die andring mold in two forms,its effect is to improvetransport and storage capacity of biomass materials,improving combustionperformance, improve efficiency, and reduce the generation of post-combustion of harmful substances.

Vertical ring mold particles machine for repression of poorlyadherent, difficult forming materials, such as: rice husk, sunflowerseedshells, peanut shells and other shell fruits; branches, tree trunk,barkand other wood weaste ; crop straw, eucalyptus,palm silk, coffee husks,coconut shell, wood and the like.Widely used in re-use of biofuel plants,power plants, wood processing plarts, fertilizer plants, chemical plants,food plants,brewweries and other waste scraps,high denasity granualation molding equipment.

Drum dryer is widely used in drying materials, metallurgy. chemical, fertilizer, cement, mining. and other irdustries in different materials. Itfeatures reasonable structure, high efficiency,energy saving,easy to operate.

The machine has a unique cooling principle, cooling wind and high temperature and high humidity material reverse movement, so that the material gradually cooled from top to bottom, to avoid the general vertical cooler caused by sudden cooling of the material surface cracking, the heart of the water is difficult to distribute and other shortcomings, the cooling effect is better than the existing domestic similar products, the cooled material temperature is not higher than the external temperature of 5° C, the precipitation rate is not less than 3.8 %. The cooling machine has a good effect on the production of high-quality granular products, the storage time of granular products and the improvement of economic benefits.

Bucket measuring and packaging scale is widely used in the measuring and packaging of particles, grain, feed, soybean meal, rice, chemical raw materials and other customer materials. Full electronic weighing, double sensor balance support bucket weighing, weighing pressure balance design, to ensure the measurement accuracy; Can store 20 weighing samples, convenient and fast weight selection, equipped with remote communication interface; Unique feeding design, double cylinder drive feeding adjustable; Adapt to the changing requirements of feeding quantity, ensure high speed and high precision; Select high quality import period to ensure stable and reliable work.

Detailed Photos

Packaging & Shipping

Company Profile

FAQ

Question 1 : Is the pellet machine dry in and out?

Answer: What we usually call dry-in and dry-out means that the raw materials can be processed directly. This is a

misunderstanding. It is not a real dry-in and dry-out, because the raw materials used contain a certain percentage of moisture, as long as the overall humidity is 10 Between %-15%, there is no need to add water, and it can be done directly. If the raw materials are very dry, you can spray a little water, a small amount, about 3%-5%, so that it can be formed well and will not affect storage.

Question 2 : Does the pellet machine have any requirements for raw materials?

Answer: Grain materials do not need to be crushed, but forage and straw must be crushed before they can be processed. It is best to use powder materials because the particles made from powder materials are evenly nutritious.

Question 3 : Can we not use your motors and equip them locally?

Answer: Of course, it is convenient for maintenance in the future, and can save freight! But our price is not the price of the

motor! Our motors are 100% national standard copper core from regular manufacturers, the price is more expensive, and the quality Completely rest assured!