- Overview

- Product Description

- Widely Application

- Our Advantages

- Product Parameters

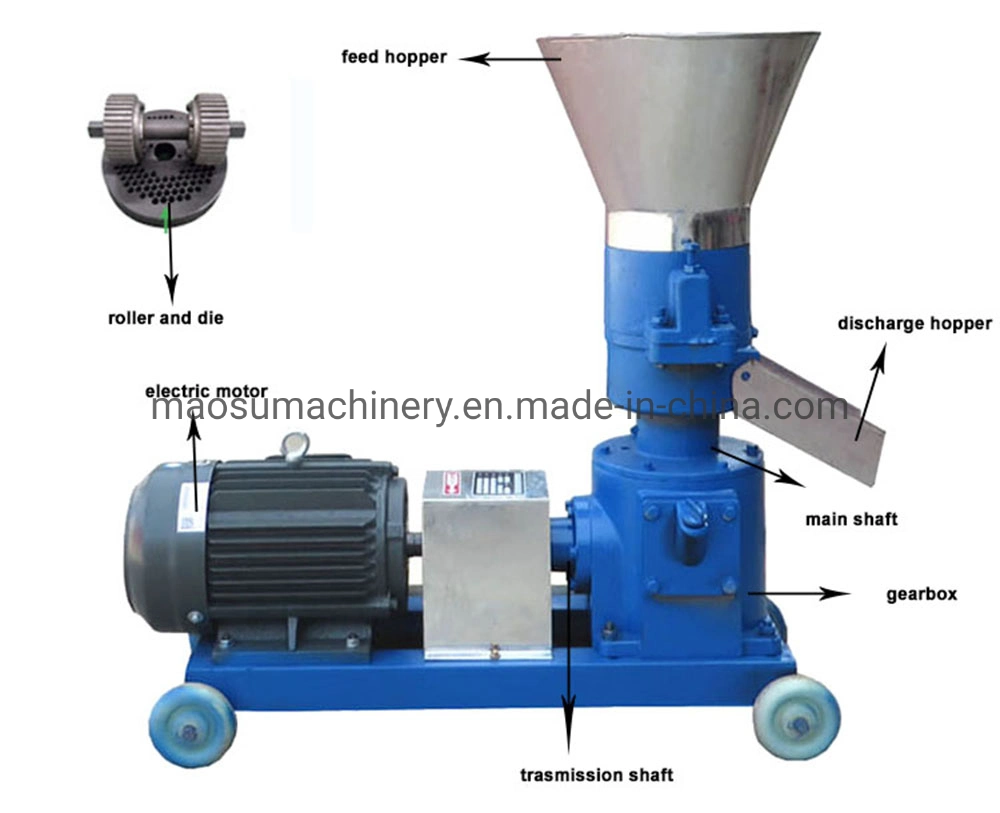

- Detailed Photos

- Animal Feed Production Line

- Packaging & Shipping

- Company Profile

Basic Info.

Product Description

The feed pellet mill is a feed processing machine that directly compresses the pulverized raw materials such as corns, soybean meals, straws, grass, rice hulls, etc. The feed pellet mill is a feed processing machine that directly compresses the pulverized raw materials such as corns, soybean meals, straws, grass, rice hulls, etc. into pellets, and the process of pellet formation will cause the denaturalization of pancreatic enzyme resistance factors in cereals and beans, which will kill a variety of parasitic ovum and other pathogenic microorganisms, and reduce various parasites and digestive system diseases, thereby improving the digestion and absorption of nutrients.Manufacturer cheap efficiency small straw pellet mill making machinery.

1.Feed pelelt mill machine is mechanical equipment that specializes in making animal poultry feed. For example, it can produce chicken feed, cattle feed, sheep feed, pig feed, horse feed, cat food, dog food, fish feed, shrimp feed, and so on.

1.Feed pelelt mill machine is mechanical equipment that specializes in making animal poultry feed. For example, it can produce chicken feed, cattle feed, sheep feed, pig feed, horse feed, cat food, dog food, fish feed, shrimp feed, and so on.

2.Raw Materials:soybean meal, cornmeal, bran, cotton cake, rapeseed cake, soybean cake, bone meal, baking soda, premix, salt, corn stalk, wheat stalk, soybean stalk, peanut Seedlings, sweet potato seedlings, pasture, weeds, straw, distiller's grains, tofu residue, etc.

3.It makes 1.5-20mm diameter animal feed pellets. Such as 2-4mm diameter chick feed pellets and pig feed pellets.2-5mm rabbit feed pellet, 4-8mm cattle or sheep feed pellets. The last pellet length can be adjusted.Manufacturer cheap efficiency small straw pellet mill making machinery

Enlarged and widened feed hopper, a large amount 1.The length of the cutter can be adjusted freely,

2.Stainless steel output hopper

3.There are fences on both sides to solve the problem of scattered feed of feed can be added at one time

Upgraded chrome-manganese steel discs Clutch

The final grinding disc is made of chrome-manganese steel, Exquisite workmanship, long service life

which is quenched at high temperature for durability

1.feed pelelt machine can be powered by electric, diesel engine or tractor(PTO);

2.We adopt the new design of direct connection of motor shaft and he main shaft that overcome the loose defect of belt connecting as long time using;

3.High accuracy gearbox and high output;

4.It is widely used in large,middle, small scale aquatic. food and feed processing factory, livestock farm, poultry farm, individual raisers, middle and small farm;

5.International advance steam fittings and imported pressure reduction valve;

6.Flat die is made with international advanced equipment for long lifespan;

7.Drive with heavy duty gearbox, which can produce continuously in most adverse condition.Manufacturer cheap efficiency small straw pellet mill making machinery

| Model | Capacity(kg/h) | Power(kw) | Dimension(mm) | Weight(kgs) |

| 125 | 80-100 | 3-4 | 630*270*750 | 35 |

| 150 | 90-150 | 3-4 | 650*270*780 | 40 |

| 160 | 150-200 | 4.5 | 680*300*800 | 45 |

| 210 | 200-300 | 7.5 | 850*350*910 | 110 |

| 230 | 350-450 | 11 | 980*380*940 | 150 |

| 260 | 400-500 | 15 | 1080*420*1040 | 190 |

| 300 | 500-700 | 22 | 1300*510*1210 | 400 |

| 360 | 700-800 | 22 | 1400*560*1600 | 600 |

| 400 | 900-1200 | 30 | 1500*610*1800 | 750 |

Zhengzhou Maosu Machinery Equipment Co,Ltd is professional manufacture of animal food, pet food,snacks puffed food machinery and whole production plant .Our company devote ourselves to be a state-owned business mainly deal with the manufacturer ,research and development of the food machinery.Also to comply with the request of different clients`,we could design and make the whole complete processing line of different snack food,TVP textured soya protein food ,pet food,2D 3D Pellet snack food and so on.We have a factory ourselves which size is more than 10000 square meters.There are more than 40 workers, including 10 high-skilled technicians,10 experienced engineers working for us.

Zhengzhou Maosu Machinery Equipment Co,Ltd is professional manufacture of animal food, pet food,snacks puffed food machinery and whole production plant .Our company devote ourselves to be a state-owned business mainly deal with the manufacturer ,research and development of the food machinery.Also to comply with the request of different clients`,we could design and make the whole complete processing line of different snack food,TVP textured soya protein food ,pet food,2D 3D Pellet snack food and so on.We have a factory ourselves which size is more than 10000 square meters.There are more than 40 workers, including 10 high-skilled technicians,10 experienced engineers working for us.

Quality comes first,Customers come first is our basic policy,create greatest value for Clients is our base of long-term cooperation with clients.After many years' development,our machines have large domestic and overseas markets.

FAQ

1.When will you ship the machine?

Normally 7-15 working days for single machines.The time of big production line will depends on detail situation.

2.How can I buy this machine?

First talk all details of machines with our sales person, then talked about the price, and choose most economic transportation way. then you can choose the payment terms.after we getting the deposit, we start to produce the machine. last, packing and shipping the machine to you.

3.Can you guarantee your quality?

Firstly, our factory has 20 years of professional production experience. Secondly, we have advanced production equipment and professional production workers to ensure the quality of the machines. Secondly, we have 10 engineers to guarantee after-sales service, installation, operation training and post-maintenance of the machines.And we take a test on every equipment before delivery.

4.How long is your guarantee ?

One Year guarantee. We shall supply free exchange for spare parts. After this period, we shall charge at low cost to keep after service. You will be welcome to contact us with any problem might occurred.

5.If we have problems when using this machine, what should we do?

If you have any problem, just contact us, we will help you to solve it, and if necessary, we will arrange our engineers to help you in your country.

6.How about your service?

24 hours online service to solve any problem. Your satisfy is our pursuit. Sincerely hope our cooperation .