Basic Info.

Model NO.

XYG100

Condition

New

Transport Package

Standard Exportatiion Packing

Specification

ISO9001/2000

Trademark

XIANGLIANG BRAND

Origin

Hunan Xiangliang Machinery Manufacture Co., Ltd.

HS Code

8437800000

Production Capacity

50tons to 300tons Per Day

Product Description

#train Grain unloader#Train grain pump#Wagon grain unloader#Truck grain unloader#Wagon grain pump#Silo Grain Unloader#Truck Grain Unloader#loader and Unloader transport for Granary Grain Materials Capacity From 30tons to 300tons Per Day

HUNAN XIANGLIANG MACHINERY MANUFACTURE CO.,LTD professtional to produce series grain unloaders:

Port grain unloaders/Ship unloader

Storage and Silo grain unloaders ,grain pump

Grain pumps for loading different granary materials

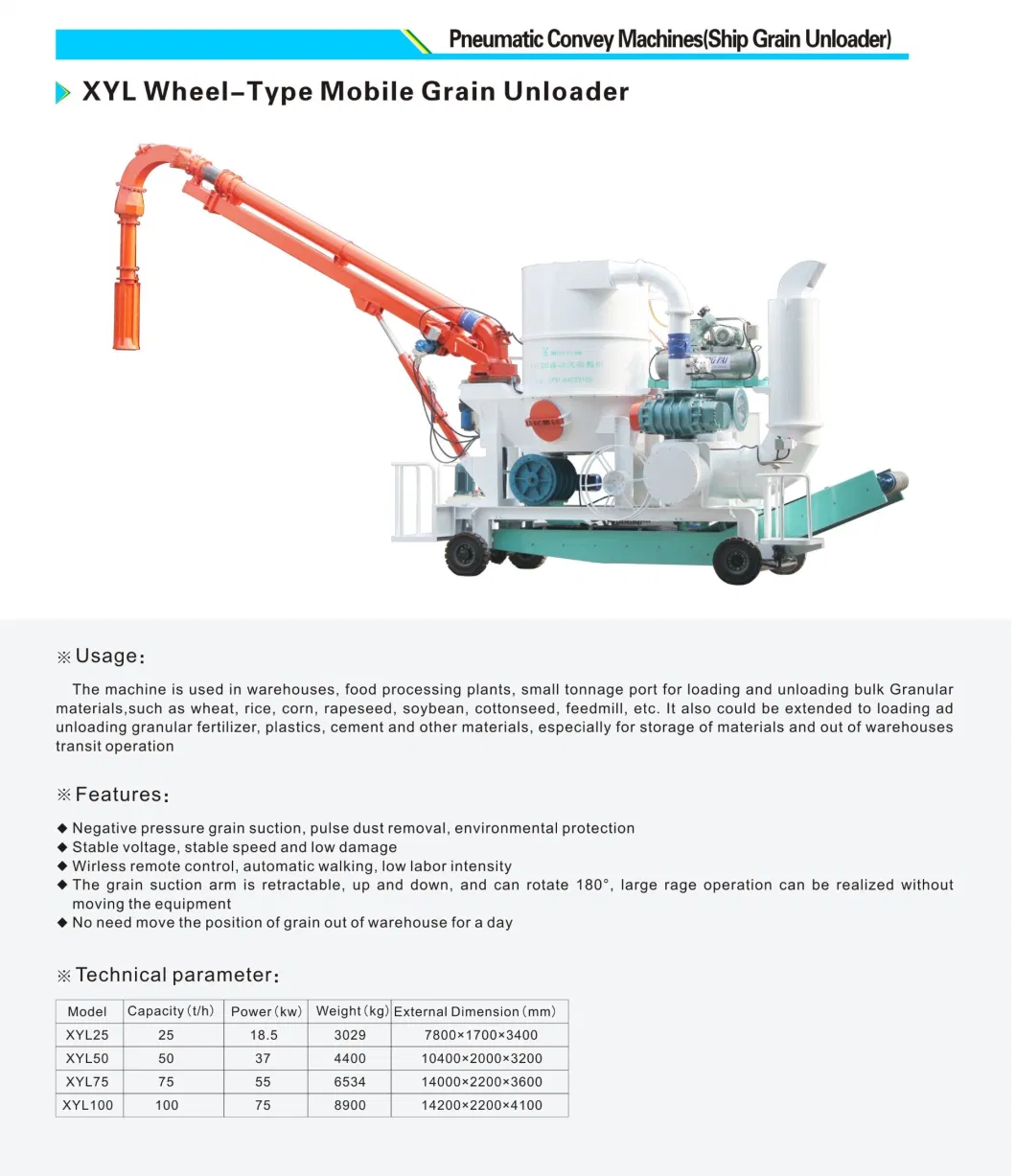

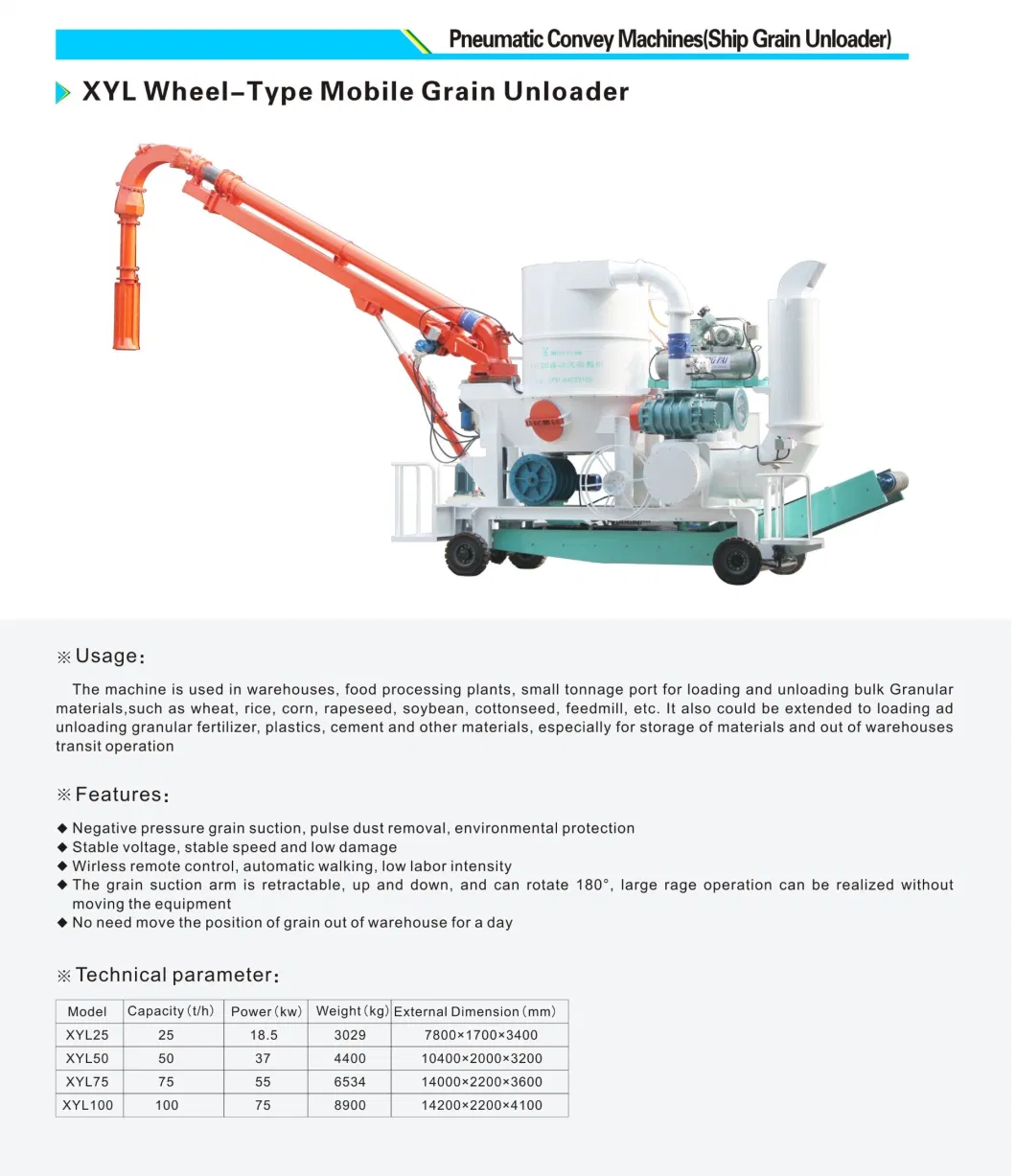

Pneumatic Convey Machines(Grain Unloader)

Port Unloader

:Usage: .

Port installed in the grain unloader to adapt to coast.Along the river,the river port for the suction unloading of bulk granular materials,such as wheat,rice,soybeans,corn,rapeseed,fodder,etc.which can be extended for granular fertilizer ,plastic,cement and other yard

:. Process layout:

According to the installation of forms,there is room-mounted,steel frame fixed,mobile and other rail

:Feature

No dust outside,environmental protection

Automatic cleaning without manual cabin cleaning

No grain scattered and wasted

Remote control operation,low labor intensity

Stable pressure andd speed ,dense phase transportation,low broken rate

High efficiency of continuous operation

HUNAN XIANGLIANG MACHINERY MANUFACTURE CO.,LTD professtional to produce series grain unloaders:

Port grain unloaders/Ship unloader

Storage and Silo grain unloaders ,grain pump

Grain pumps for loading different granary materials

Pneumatic Convey Machines(Grain Unloader)

Port Unloader

:Usage: .

Port installed in the grain unloader to adapt to coast.Along the river,the river port for the suction unloading of bulk granular materials,such as wheat,rice,soybeans,corn,rapeseed,fodder,etc.which can be extended for granular fertilizer ,plastic,cement and other yard

:. Process layout:

According to the installation of forms,there is room-mounted,steel frame fixed,mobile and other rail

:Feature

No dust outside,environmental protection

Automatic cleaning without manual cabin cleaning

No grain scattered and wasted

Remote control operation,low labor intensity

Stable pressure andd speed ,dense phase transportation,low broken rate

High efficiency of continuous operation

| Project | Model Unit | 50 | 75 | 100 | 150 | 200 | 250 | 300 |

| Capacity | t/h(Wheat) | 50 | 75 | 100 | 150 | 200 | 250 | 300 |

Arm Extension (all out) | M | 8 | 9 | 14 | 16 | 20 | 25 | 28 |

| Expan Distance | M | 3.5 | 3.5 | 6 | 7 | 9 | 10 | 12 |

| Pitch Angle | (°) | +55 -35 | +55 -35 | +55 -30 | +55 -30 | +55 -30 | +55 -30 | +55 -30 |

| Swing Angle | (°) | 180 | 180 | 180 | 180 | 180 | 180 | 180 |

| Dust In Exhaust | Mg/m3 | <60 | <60 | <60 | <60 | <60 | <60 | <60 |

| Noise Control | dB(A) | <78 | <78 | <78 | <78 | <78 | <78 | <78 |

| Power | kw/Set | 55 | 65 | 110 | 130 | 180 | 250 | 300 |

| For Ship | t(Type) | 300 | 500 | 3000 | 5000 | 15000 | 20000 | 30000 |