Basic Info.

Model NO.

OEM

Processing Technics

Mixing-before-Crushing

Screen Mesh

With Screen Mesh

Grinding Equipment Type

Feed Hammer Mill

Pellet Mill Type

Ring Die Pelleter

Bulking Machine Type

Twin Screw Bulking Machine

Expanding Method

Wet Expansion

Condition

New, New

Applicable Materials Shape

Short strip

Warranty

One Year Guarantee, 1 Year

Voltage

380V

Controlling Mode

CNC

Energy Saving

Energy Saving

Customized

Customized

Automatic Grade

Customized

Color

Customized

Hardness

58-62HRC

Guarantee

One Year Against Quality Defects

Quality Control System

Ts 16949, ISO 9001

Max Manufacture Ability

1000 Tons Per Month

MOQ

10PCS

Transport Package

ISO Standard

Specification

ISO 9001

Trademark

OEM

Origin

Qingdao, Shandong

HS Code

73084000

Production Capacity

100tons/Month

Packaging & Delivery

Package Size

1100.00cm * 800.00cm * 750.00cm

Package Gross Weight

1160.000kg

Product Description

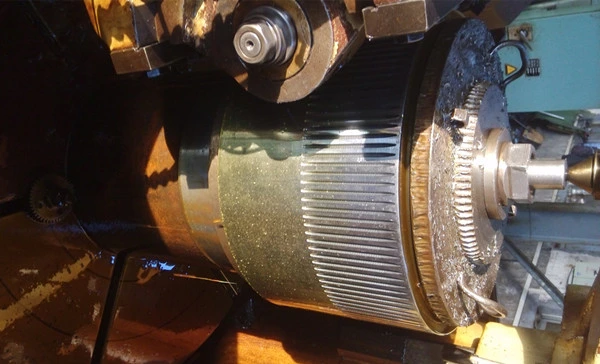

Agro Processing Equipment Pellet Press Roller Shells

Product Description

Roller Shell is one of the primary working components for pellet mill, which is used to process different kinds of biomass pellet fuel, feed pellet, wood pellet and so on.

Outer diameter:220mm Inner diameter:130mm Width:88mm (Custom dimensions and drawings of roller shells are welcome.)

Surface processing form:Open corrugated(open slotted)

Material:50# carbon steel

Hardness:HRC 58-62

Service life:More than 400 hours

Packing Details:

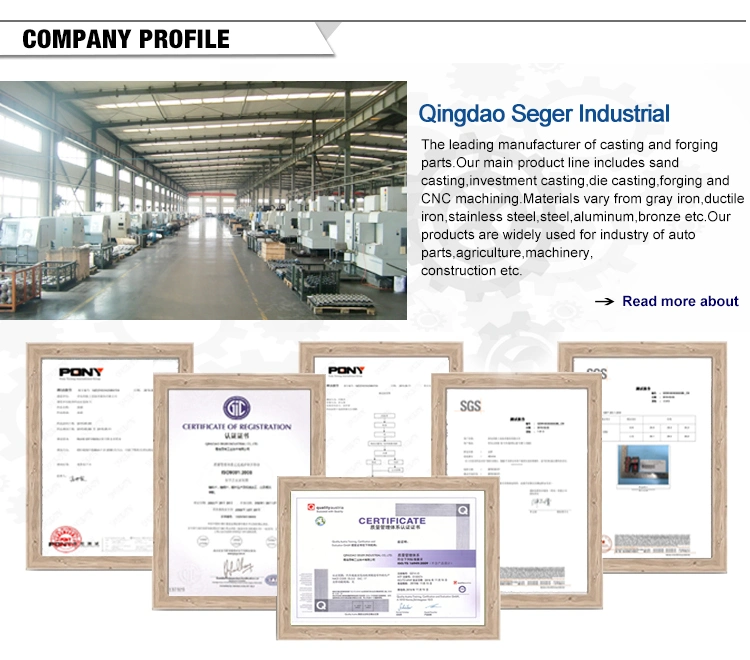

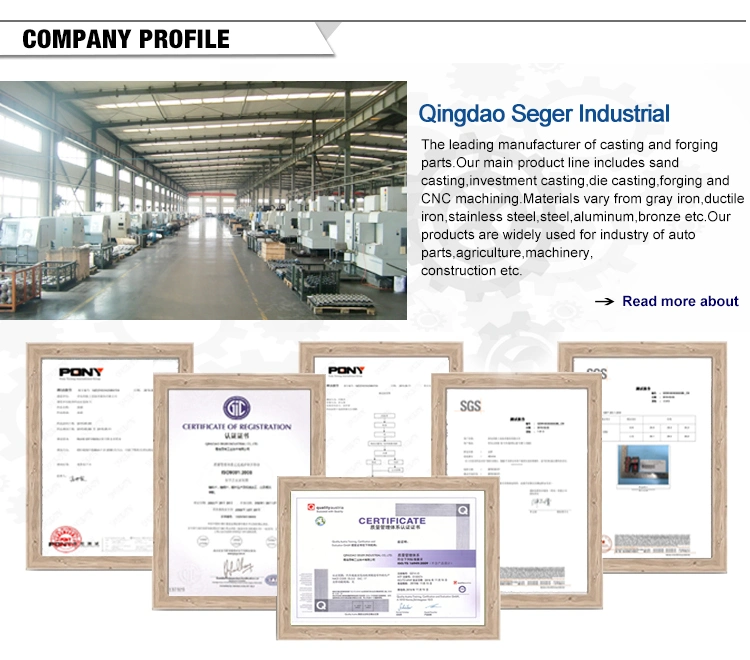

Company Information

We will design each special mold to control key dimensions of roller shell in every process.We can ensure each key dimension under control.

FAQ

Frequently Asked Questions

Q1:What is your MOQ?

A1:Our MOQ is 100 pieces.

Q2:Do you offer free sample?

A2:We can provide you a sample but you need to pay for it and also the freight.

Q3:What is your payment term?

A3:30% down payment after confirming the contract/PI and the balance before shipment/copy of Bill of Lading.

Q4:What normal cooperation processes do you have?

First, we need your drawing for quotation.

Second, you accept our quotation, then you pay for the tooling cost and we will arrange to make the sample on approval.

Third, you approve with the sample and we make sales contract for you to confirm.

Fourth, manufacturing products and shipping to you.

Fifth, you pay us the balance.

Finally, you receive roller shell and feedback.

Product Description

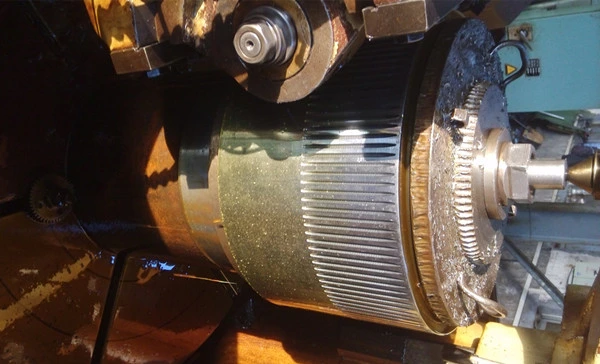

Roller Shell is one of the primary working components for pellet mill, which is used to process different kinds of biomass pellet fuel, feed pellet, wood pellet and so on.

Outer diameter:220mm Inner diameter:130mm Width:88mm (Custom dimensions and drawings of roller shells are welcome.)

Surface processing form:Open corrugated(open slotted)

Material:50# carbon steel

Hardness:HRC 58-62

Service life:More than 400 hours

| Process | Hot forging, die forging and Free forging |

| Material | Carbon steel: 1020,1020,1035,1045,1055,Q235,Q345 etc., Alloy steel: 40Cr, 20CrMnTi, 20CrNiMo,35CrMn,42CrMo4 etc., Stainless steel, SS304,SS316 etc. |

| Standard | ISO, DIN, ASTM, BS ect. |

| Weight | 0.1kg - 120kg |

| Applicable Machining Process | CNC Machining/ Lathing/ Milling/ Turning/ Boring/ Drilling/ Tapping/ Broaching/Reaming etc. |

| Machining Tolerance | 0.02mm-0.1mm |

| Machined Surface Quality | Ra 0.8-Ra3.2 according to customer requirement |

| Applicable Heat Treatment | Normalization , quenching and tempering, Case Hardening, Nitriding, Carbon Nitriding, |

| Applicable Finish Surface Treatment | Shot/sand blast, polishing, Surface passivation, Powder coating, E- Coating, Chromate Plating, zinc-plate, Dacromat, Painting, |

| Testing equipment | Supersonic inspection machine, Supersonic flaw detecting machine , physics and chemical analysis. |

| Packing | Wooden cases or according to customers' needs |

| MOQ of mass production | 1000-5000pcs |

Packing Details:

- Bubble bag and color box per piece used for sales directly, many boxes per carton box, then packed in standard export plywood case/pallet

- Carton box+standard export plywood case/pallet

- Bubble bag per piece, then packed in standard export plywood case directly

- Export plywood case directly

Company Information

We will design each special mold to control key dimensions of roller shell in every process.We can ensure each key dimension under control.

FAQ

Frequently Asked Questions

Q1:What is your MOQ?

A1:Our MOQ is 100 pieces.

Q2:Do you offer free sample?

A2:We can provide you a sample but you need to pay for it and also the freight.

Q3:What is your payment term?

A3:30% down payment after confirming the contract/PI and the balance before shipment/copy of Bill of Lading.

Q4:What normal cooperation processes do you have?

First, we need your drawing for quotation.

Second, you accept our quotation, then you pay for the tooling cost and we will arrange to make the sample on approval.

Third, you approve with the sample and we make sales contract for you to confirm.

Fourth, manufacturing products and shipping to you.

Fifth, you pay us the balance.

Finally, you receive roller shell and feedback.