- Overview

- Product Description

- Product Parameters

Basic Info.

Model NO.

SD-MF30

Press Materials

Corn

Press Series

Second

Condition

New

Customized

Customized

Capacity

30t/D

Transport Package

Wooden Case

Specification

15m*6m*5m

Trademark

Sida

Origin

China

HS Code

8437800000

Production Capacity

500set/Year

Product Description

SIDA maize flour mill machine is suitable for flour processing plants

The 10-200 ton maize flour processing equipment achieves a daily processing capacity of 10-200 tons of raw corn grains, and uses the full dry process to process corn kernels, corn flour and corn grits of different particle sizes.

The corn processing equipment is easy to operate, has high output and low power consumption, and can complete corn cleaning, peeling, embryo removal, root removal, black umbilical removal, crushing, grit removal, grading, polishing, selection and other processes at one time.

The finished corn after finishing is smooth in appearance, uniform in particles and fresh in color and husk. Direct access to the grain and oil market.

The maize mainly have three parts: germ, bran and endosperm.

Endosperm is mainly for get fine maize product, like maize flour, maize grits maize rice and so on.

Germ and peel are mainly by-products with for animal feeding

From maize to fine products, it need though cleaning system to clean maize well and degermintor remove all germ and peel from maize, to get cleaned and well Endosperm to prepare produce good quality maize final products. then the endosperm go to milling section to mill it in to flour /meal /grits/ rice depend on designing.

The maize mainly have three parts: germ, bran and endosperm.

Endosperm is mainly for get fine maize product, like maize flour, maize grits maize rice and so on.

Germ and peel are mainly by-products with for animal feeding

From maize to fine products, it need though cleaning system to clean maize well and degermintor remove all germ and peel from maize, to get cleaned and well Endosperm to prepare produce good quality maize final products. then the endosperm go to milling section to mill it in to flour /meal /grits/ rice depend on designing.

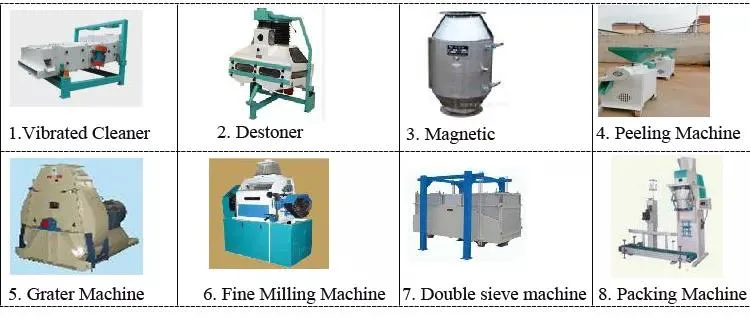

Main components of corn flour machine

| Product | Quantity | Unit Power(kw) | Total Power |

| Combined vibrate cleaner & destoner | 1 | 0.25*2 | 0.5 |

| Magnetic selector | 4 | | |

| Polisher | 2 | 15 | 30 |

| Pulverizer | 1 | 75 | 75 |

| Single warehouse screen | 1 | 1.1 | 1.1 |

| Unloader | 2 | / | / |

| Packing counter | 3 | / | / |

Flow chart:

Flow chart:

Input maize --maize cleaner and destoner--maize moisture dampener --degerminator--roller mill--plansifter-super maize meal/special maize meal/maize grits--packing.

Description:

1. Cleaning part:

To clean out the middle and small impurity from wheat. e.g., dust, stone, magnetic material, maize was bitten by insect and so on.Includes beating, screening, destoner, magnetic separator and dampening. This section is make the maize/corn to prepare for milling part and to protect the machinery as well.

2. Milling part:

Include different number of mill and sifter to mill the wheat and separate the flour and bran

(1) Mill: mill the wheat to break the integrity by the roller moving

(2) Sifter: to separate the flour and bran, also separate large size and small size to ensure flour quality.

3. Packing part:

The packing part can be manual one also can be auto one, this can be designed according to requirement and machine capacity.

4. PLC controlling system:

To control the whole set of machinery to work well and showing the process of working

To clean out the middle and small impurity from wheat. e.g., dust, stone, magnetic material, maize was bitten by insect and so on.Includes beating, screening, destoner, magnetic separator and dampening. This section is make the maize/corn to prepare for milling part and to protect the machinery as well.

2. Milling part:

Include different number of mill and sifter to mill the wheat and separate the flour and bran

(1) Mill: mill the wheat to break the integrity by the roller moving

(2) Sifter: to separate the flour and bran, also separate large size and small size to ensure flour quality.

3. Packing part:

The packing part can be manual one also can be auto one, this can be designed according to requirement and machine capacity.

4. PLC controlling system:

To control the whole set of machinery to work well and showing the process of working

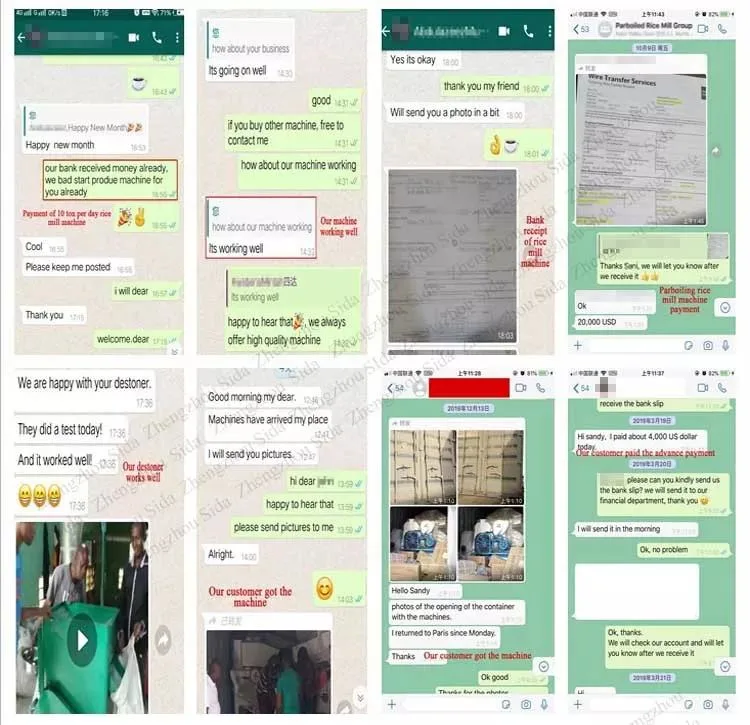

Customer Visit & Feedback

Please send email and message to us for more information and detailed price offer ,thanks.

Please send email and message to us for more information and detailed price offer ,thanks.